Type 99

7

location. The line or stack opening must

be protected against condensation,

freezing, and clogging.

Clean out all pipelines before installation and check

to be sure the regulator has not been damaged or

collected foreign material during shipping.

Apply pipe compound to the male pipe threads only with

a screwed body, or use suitable line gaskets and good

bolting practices with a flanged body. This regulator

may be installed in any position desired as long as the

flow through the body is in the direction indicated by the

arrow on the body. Install a three-valve bypass around

the regulator if continuous operation is necessary during

maintenance or inspection.

Although the standard orientation of the actuator and

pilot to the main valve body is as shown in Figure 1, this

orientation may be changed as far as the inlet tubing

(key 24, Figure 9 or 11) will permit by loosening the

union nut (key 14, Figure 9), rotating the actuator lower

casing (key 29, Figure 9) as desired, and tightening

the union nut. To keep the pilot spring case from being

plugged or the spring case from collecting moisture,

corrosive chemicals, or other foreign material, the vent

must be pointed down, oriented to the lowest possible

point on the spring case, or otherwise protected. Vent

orientation may be changed by rotating the spring

case with respect to the pilot body, or on the extra

high pressure pilot with optional tapped spring case by

rotating the vent with respect to the spring case.

To remotely vent a low pressure pilot, install the vent

line in place of the pressed-in vent assembly (key 60,

Figure 9). Install obstruction-free tubing or piping

into the 1/4-inch (6,35 mm) vent tapping. Provide

protection on a remote vent by installing a screened

vent cap into the remote end of the vent pipe.

To remotely vent a high pressure pilot, or an extra high

pressure pilot with optional tapped spring case, remove

the screwed-in vent assembly (key 72, Figure 9) from

the high pressure pilot spring case or the pressed-in

vent assembly from the extra high pressure pilot

spring case and install obstruction-free tubing or piping

into the 1/4-inch (6,35 mm) vent tapping. Provide

protection on a remote vent by installing a screened

vent cap into the remote end of the vent pipe.

An upstream pilot supply line is not required because

of the integral pilot supply tubing (key 24, Figure 9

or 11). However, as long as the 1/4-inch NPT

tapping in the main valve body is plugged, this

tubing may be disconnected from both the main

valve and filter assembly (key 75, Figure 9) in order

to install a pilot supply line from a desired remote

location into the filter.

If the maximum pilot inlet pressure will be exceeded

by main valve pressure, install a separate reducing

regulator (if not already provided) in the pilot supply line.

A Type 99 regulator has two 1/2-inch threaded NPT

control line pressure taps on opposite sides of the

lower casing (key 29, Figure 9). The regulator normally

comes from the factory with the tap closest to the

regulator outlet left unplugged for the downstream

control line as shown in Figure 1, and with opposite

tap plugged.

Attach the control line from the unplugged tap 2 to

3 feet (0,61 to 0,91 meter) downstream of the regulator

in a straight run of pipe. If impossible to comply with

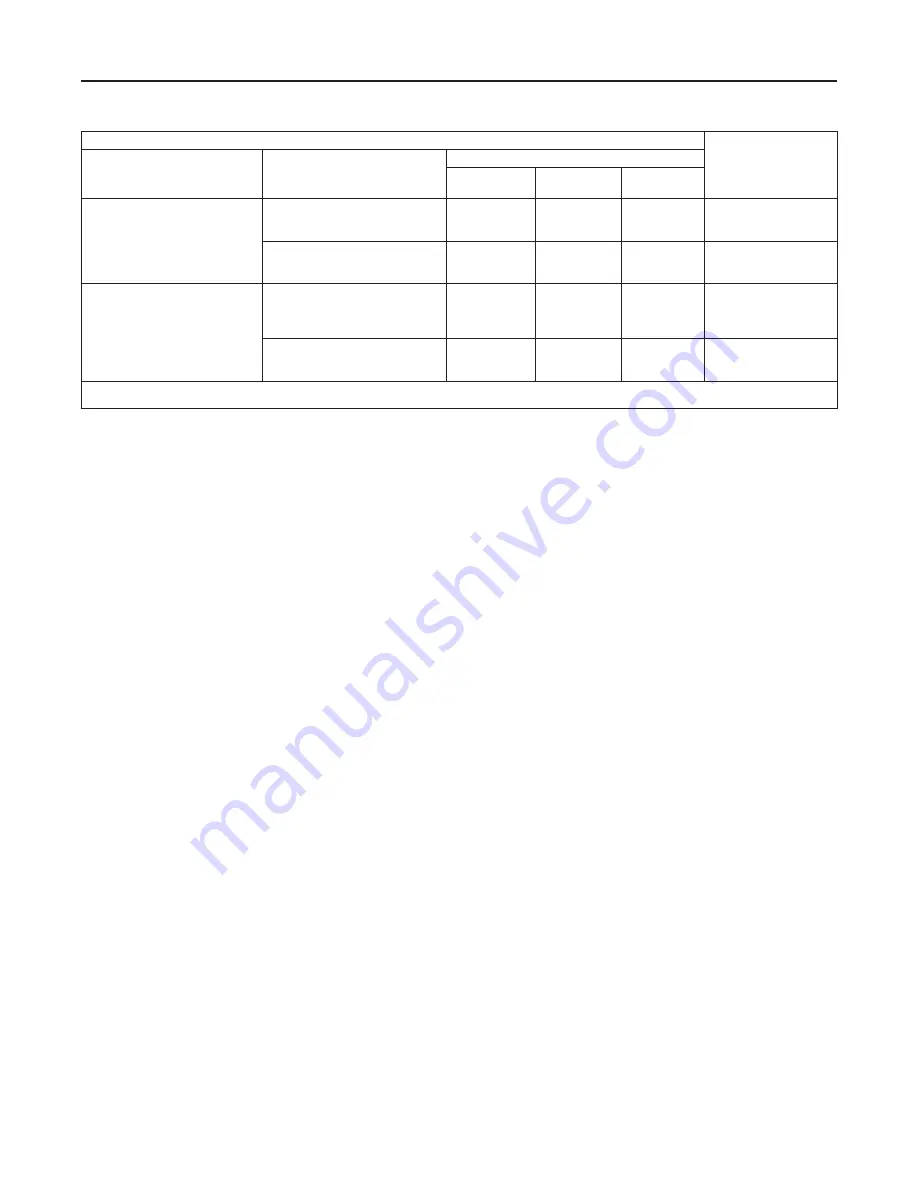

Table 4.

Working Monitor Performance

MOnITORIng PILOT InFORMaTIOn

MInIMUM PRESSURE

aT WHICH WORKIng

MOnITOR REgULaTOR

Can BE SET

Construction

Spring Range

Pilot Spring

Part number

Wire Diameter,

Inches (cm)

Free Length,

Inches (cm)

Type 161AYW with 1/8-inch

(3,18 mm) port diameter and

150 psig (10,3 bar) maximum

allowable inlet pressure

5 to 15-inches w.c. (12 to 37 mbar)

11 to 28-inches w.c. (27 to 70 mbar)

1B653927022

1B537027052

0.105 (0,27)

0.114 (0,29)

3-3/4 (9,52)

4-5/16 (11,0)

3-inches w.c. (7 mbar)

over normal

distribution pressure

1 to 2.5 psig (0,069 to 0,17 bar)

2.25 to 4.5 psig (0,16 to 0,31 bar)

4.5 to 7 psig (0,31 to 0,48 bar)

1B537127022

1B537227022

1B537327052

0.156 (0,40)

0.187 (0,47)

0.218 (0,55)

4-1/8 (10,5)

3-15/16 (10,0)

4-1/8 (10,5)

0.5 psi (0,03 bar)

over normal

distribution pressure

Type 627-109 with 1/8-inch

(3,18 mm) port diameter and

150 psig (10,3 bar) maximum

allowable inlet pressure for cast

iron body or 750 psig (51,7 bar)

maximum allowable inlet pressure

for malleable iron body

5 to 15 psig (0,34 to 1,03 bar)

10 to 25 psig (0,69 to 1,72 bar)

20 to 35 psig (1,38 to 2,41 bar)

25 to 60 psig (1,72 to 4,14 bar)

1D892327022

1D751527022

1D665927022

1D755527142

0.168 (0,43)

0.187 (0,47)

0.218 (0,55)

0.500 (1,27)

2-15/16 (7,46)

2-13/16 (7,14)

2-15/32 (6,27)

9-1/4 (23,5)

3.0 psi (0,21 bar)

over normal

distribution pressure

40 to 80 psig (2,76 to 5,52 bar)

80 to 150 psig (5,52 to 10,3 bar)

130 to 200 psig (9,00 to 13,8 bar)

1E543627142

1P901327142

(1)

1P901327142

(2)

0.283 (0,72)

0.240 (0,61)

0.240 (0,61)

2-15/16 (7,46)

2-5/8 (6,67)

2-5/8 (6,67)

5.0 psi (0,34 bar)

over normal

distribution pressure

1. With large diaphragm plate.

2. With small diaphragm plate.