DOUBLE DOOR FRAME ASSEMBLY

Procedure for assembly of one of the doors, 2

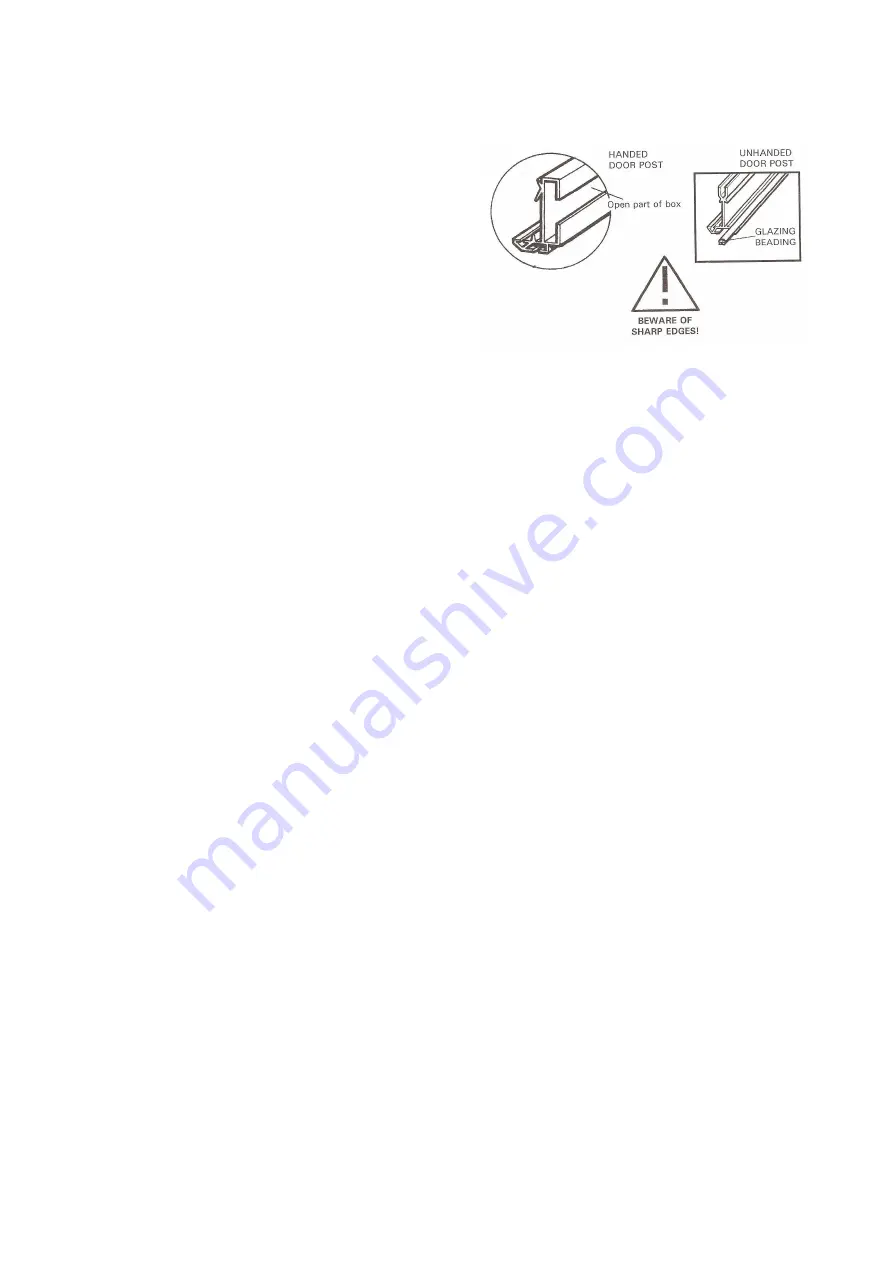

nd

door procedure is the same except handed/unhanded

door position is reversed.

Each door component consists of:

2 door glazing bars 1 = handed, 1 = unhanded

3 infill panels

2 top and bottom door panels

From the main bag of fittings you require:

2 door wheels

1 Nylon door skid (this may have been fitted prior to delivery)

1 length of black draught excluder

Double Door catch, self tapping screws and spring washers.

1. Place the two side bars on a level surface roughly 24” apart with the bolt slots facing down-

wards. The top of each side piece has two screw holes in it, the bottom has three (

Key point

).

2. Looking at the handed door posts in profile with the 2 holes at the top (3 holes at the bottom) the

open box part of the section goes to the outside i.e. on right hand door – right hand upright, on left

hand door – left hand upright.

3. Place the top, bottom and 3 infill panels in position as shown by the position of the screw holes

in the side pieces and the panels. The top panel has the greenhouse name on it. The bottom panel

has the edge for the door skids to fit on. The lower infill panel locks on to the bottom panel.

4. Fix the door together by screwing through the door side pieces into the holes provided in the

edge of the panels with the No.8 half-inch self–tapping screws. The screws will go in more easily

and without danger of trying to go crooked if you put a small amount of grease on the screw before

assembling the doors.

Alternatively, you could insert the screws into the screw eyes of the door panels before assembling

the door, this would have the effect of pre self-tapping the panels prior to assembly, making assem-

bly easier.

5. Make sure all the angles are square and tighten all screws.

6. Fix each door wheel into position by pushing the bolt provided through the centre of the wheel

and then through the hole in the top door panel from underneath (i.e. from the inside of the door).

Put the washer over the bolt and secure with the nut provided, tightening until there is no movement

on the bolt. The nuts are lock-nuts and are harder to put on than the normal nuts in general assem-

bly. The wheel will revolve freely because it has ball bearings on it.

7. Slip the nylon door skid on the bottom panel. (this may already be done prior to delivery)

8. Turn the door over and insert the black rubber draught excluders in the groove (bolt slot) in each

side piece of the door. Push up to the top of the door and trim off surplus at the bottom. To prevent

the draught excluder from slipping down, insert a nut and bolt at the bottom of the door post and

tighten.

9. Do exactly the same with the right hand door remembering that the draught excluder is inserted

into the right hand bar i.e. unhanded one.

10. Do not fit the doors to the front at this stage, wait until the structure is fully assembled prior to

glazing.

Summary of Contents for KENSINGTON 10 x 6

Page 1: ......

Page 2: ......

Page 3: ......

Page 17: ...DOOR FRAME...

Page 36: ...6 WIDE LT TOUGHENED GLASS PLAN Glass pane for standard door on gable end Louvre on rear end...

Page 39: ...OPTIONAL EXTRAS RAIN WATER KIT FOR GUTTERING...

Page 40: ...ELITE 1407...