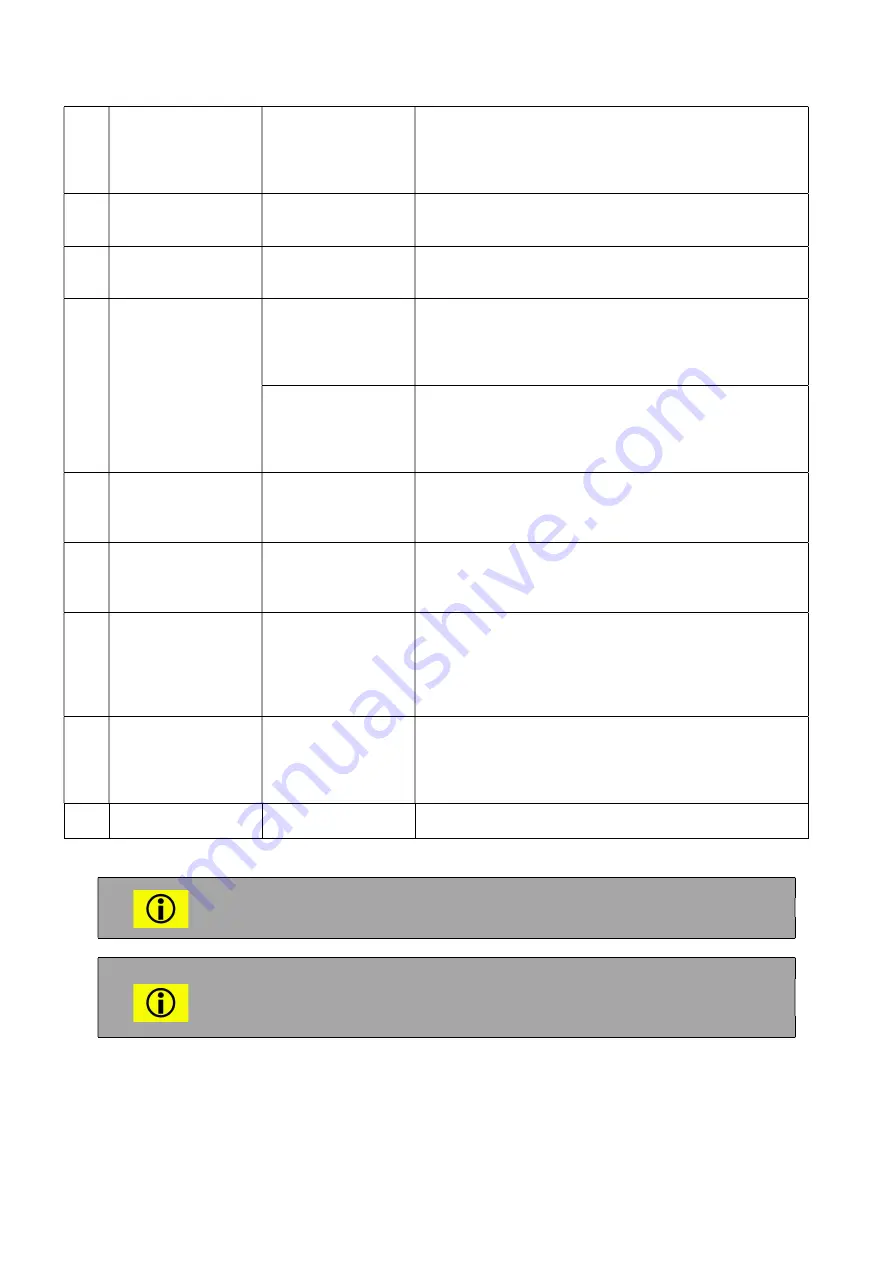

Pellet burner GP xx sc 39

temperature sticker,

positioned on the

pellets inlet pipe of

the burner

temperature in this

pipe, which in most

cases is caused by

hot gasses passing

through it

check the pellet burner condition - to be performed by

specialist.

16.

Dirty and/or melted

photic sensor

Improper stopping of

the burner’s

operation

It is necessary to clean the photic sensor’s surface or to

replace it with new one. The burner’s stopping procedure,

as presented in this manual book, must be observed.

17.

Presence of

unburned fuel in the

ash tray

Inefficient fuel

combustion

It is necessary to adjust the appliance’s operational

parameters – ask authorized servicing technicians for

consultation and/or to perform adjustments.

18.

Too many slag

deposits in the

burner’s combustion

chamber (melted

mineral mass)

The used fuel is with

high ash content and

does not comply with

the requirements of

the appliance

Change the fuel with type which complies with the

requirements for reliable operation of the burner.

The burner operates

in a mode with

heating output higher

than its nominal

output

Decrease the heating output of the burner by changing its

output level.

19.

A failure code,

indicated on the

controller’s display

panel

Trouble in the

operation of the

burner

Check the meaning of the indicated failure code in the

next table. If necessary look for consultation/intervention

by servicing technician.

20.

The

burner

has

stopped, but after a

new start it operates

again

The photic sensor

submits faulty

information to the

controller

Check the fuel quantity over the fire-grate. Look for

assistance or consultation by servicing technician.

21.

High temperature of

the flue gas (if a

thermometer is

installed)

Dirty heat

exchanging surfaces,

depending on the

consuming appliance

type and the

operation modes

It is necessary to clean the appliance’s heat exchanging

surfaces.

22.

Smoke in the boiler

room after a certain

period of operation

Dirty or clogged from

dust flue extraction

tract of the heat

energy consuming

appliance

Clean the heat energy consuming appliance from the ash

deposits.

23.

Another, not

described failures

Ask for assistance by servicing specialist or company.

* The heating of the pellets inlet pipe in most cases is caused by

contamination of the heat exchanging surfaces of the appliance, to which

the pellet burner is mounted;

** In case of insufficient chimney draught it is recommended to look for

servicing assistance in order to solve the problem – cleaning or change of the

chimney might be required, as well as installation of additional flue extraction

fan or another solution.