6

4.2.2 Pump

1. Remove dust caps from drive end and inspection end

bearing housings.

2. Remove lockwashers and locknuts from both inspection

end and drive end of shaft.

3. Remove both bearing housings. (To remove bearing

housing, screw two of the bearing housing setscrews into

the tapped holes provided in the bearing housing. Evenly

tighten the setscrews to withdraw the bearing housing.)

Take care not to damage the mechanical seal faces.

4. Press out the ball bearings from the bearing housings.

5. Remove the bearing dampening O-Rings from the shaft

then carefully remove the mechanical seal components

from both the bearing housings and from the rotor/shaft

assembly.

6. Remove body covers and wearplates (To remove body

cover, screw four of the bearing housing setscrews into

the tapped extraction holes provided in the body cover.

Evenly tighten the setscrews to withdraw the body cover.)

7. Withdraw the rotor/shaft/vane assembly from the body

taking care to support the vanes as the assembly is

withdrawn.

8. Remove vanes and pushrods from the rotor (note the

orientation of the vanes relative to the direction of

rotation)

9. Remove liner from body (note the orientation of the liner

relative to the inlet and discharge ports of the body.

10. Remove grease nipples and pressure release plugs from

the bearing housings.

11. Remove oil seal from drive end dust cap.

4.3

INSPECTION

NOTE:

Optimum

performance

is

achieved

by

maintaining

the

pump

within

the

following

guidelines.

Adequate performance may still be achieved

dependent on application parameters

.

1. Inspect rotor/shaft assembly and liner. If damage or

excessive wear is evident, it is recommended to replace

both components. Scoring in the seal zones of the liner is

detrimental to optimum performance.

NB:

The rotor is permanently attached to the shaft.

2. Inspect both mechanical seals. Replace mechanical seal

assembly if components are worn or damaged

3. Inspect vane pushrods for wear, damage and

straightness. Replace the pushrods if they show signs of

physical damage, wear or distortion e.g. mushroomed,

rounded or tapered ends, scoring on flanks, bending,

etc.

4. Inspect vanes for wear or damage. Replace if damaged

or excessive wear is evident. Check for scoring on vane

tips.

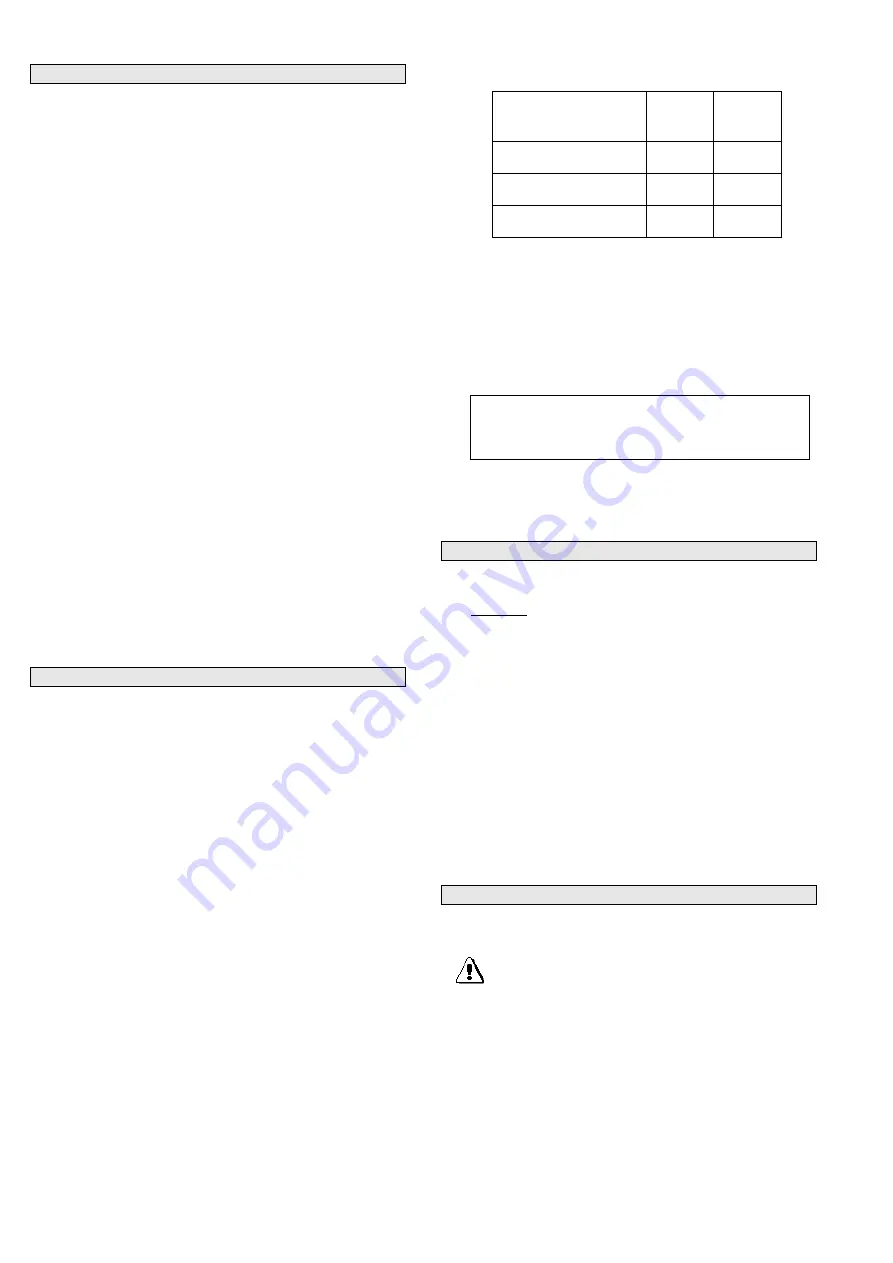

Recommended Minimum

Worn Vane Sizes

Vane

Length

Vane

Height

V2000

74.62mm

27.00mm

V3000

89.62mm

28.00mm

V3010

89.62mm

28.00mm

5. Inspect pressure relief valve assembly and components

for wear or damage. Replace or refurbish as required.

6. It is recommended that all O-Rings and lip seals be

replaced at every overhaul.

7. Inspect both ball bearings for wear. It is recommended

on major overhauls that ball bearings be replaced.

8.

Ensure pressure relief ducts in bearing housings are not

obstructed

.

4.4

SPARE PARTS

1. When ordering spare parts, to ensure a minimum of

delay and correct replacement to original specification,

ALWAYS quote the pump Serial Number located on the

nameplate of the pump.

2. Advise the name, Cat # and quantity required. Refer

Section 5

– Parts Designation.

3. Advise complete delivery instructions, transportation,

etc.

NOTE:

Substitute or so-

called ‘equivalent’ item/spare

parts are not recommended for use.

Compliance, safe operation and pump performance

may be severely compromised if incorrect or substitute

spare parts

– including Fasteners, O-Rings, Ball

Bearings, etc

– are used.

Only use genuine Ebsray spare parts.

4.5

REASSEMBLY - PRELIMINARY

1. Ensure all parts are clean and deburred before

assembly.

At all times when handling and

installing mechanical seals,

care must be taken to ensure lapped faces and seats

are not damaged. Particular attention must be given to

carbon seats to prevent marking or chipping.

2. Lubricate all O-Rings and lapped faces of mechanical

seals with a good quality, compatible, detergent-free

light oil before assembly.

3. Pack Ball Bearings with a good quality, suitable grease.

4. Ensure correct orientation of components relative to

pump rotation/handing .

CAUTION

DANGER

Ball Bearing Replacement interval should not exceed

V2000

10,000 operational hours

V3000

5,000 operational hours

V3010

5,000 operational hours

Summary of Contents for V Series

Page 9: ...9...

Page 12: ...12 NOTES...