Section IV

Cleaning

6 EATON

Aerospace Group

TF100-63B October 2018

1. General

It is recommended that all hose assemblies and

component parts be thoroughly cleaned and

degreased before inspection.

A.

Cleaning Hose Assemblies with AE102/624 Fire

Sleeve — It is suggested that the fire sleeve

be completely removed before cleaning. When

cleaning after proof test, installation of the fire

sleeve should be the last operation performed.

B.

Cleaning Hose Assemblies without Fire Sleeve

— Flush hose assembly in cleaning fluid and

brush, if necessary, to dislodge deposits. (For

information covering F-2244 Hose Wash Stand,

contact Eaton’s facility, Jackson, MI.

C.

Cleaning Fitting Component Parts — Dip

components parts and blow dry with clean air.

Caution:

Do not wire brush parts.

D.

Cleaning Fluids — The following fluids may be

used for cleaning PTFE hose assemblies.

Caution:

All dry filmed parts should be thoroughly

dried after cleaning and before reuse.

E.

Hose Assemblies After Proof Test — Flush

hose assembly in cleaning fluid and blow dry

with filtered air or dry nitrogen.

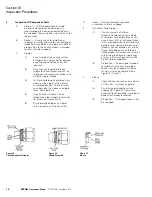

Table II

Fluids for Cleaning PTFE Hose Assemblies

Fluid

Specification

Hose Assemblies:

Oleum Spirits

Commercial

Kerosene

P-S-661

Trichloroethylene

MIL-T-7003 or OT634-A. Type II

*Synthetic Detergents

MIL-D-16791

Fitting Components:

Trichloroethylene

MIL-T-7003 or OT634-A. Type II