12

EATON

Aerospace Group

TF100-63B October 2018

Section VII

Assembly Procedure — Machine Tool Method

1.

General

The following approved equipment is recommended for

production assembly of the hose assemblies covered by

this manual:

Machine equipment should be selected according to

the individual need of the particular operator.

2.

Assembly Of Fitting To Hose

Step1. The general procedure described in Section VI,

Assembly Procedures — Hand Tool Method,

shall be followed. In addition, the following

supplemental instructions will apply when

using machine equipment for assembly.

Specific instructions for operation, use, and

maintenance of the equipment are included

in the appropriate handbook for the particular

type of equipment.

Step 2. Sleeve preseating, socket preseating, and

tube neck down can be accomplished by

machine when using the following tools:

Hose

Size

Sleeve

Preseating

Tool

Socket

Preseating

Mandrel

Neck Down

Tool

-4

S1272-7-1

S1272-3-1

F2717-6-7

-6

S1272-7-2

S1272-3-2

Not Required

-8

S1272-7-3

S1272-3-3

Not Required

-10

S1272-7-4

S1272-3-5

Not Required

-12

S1272-7-5

S1272-3-7

Not Required

Step 3. Select proper mandrel for the machine being

used.

Step 4. Adjust jaws on the machine head to provide

slip clearance on the nipple hex. This clearance

should be approximately .010 inch (.254 mm).

Step 5. Insert hose with socket in carriage and clamp

securely. Insert nipple assembly in head.

Step 6. Allow machine to screw the nipple into the

socket to the prescribed gap: 0.023 to 0.046

inch (.584 to 1.168 mm).

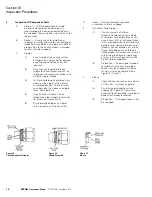

Part No.

Name

S1022

Hose Cut-Off Machine, Bench Mounted

S1229

Hose Cut-Off Machine, Bench Mounted

F2152

Hose Assembly Machine

F2197

Hose Proof Test Stand