8

EATON

Aerospace Group

TF100-63B October 2018

Section VI

Assembly Procedure — Hand Tool Method

1. General

The following steps should be followed when fabricating

hose assemblies from new or salvaged components:

Note:

Assembly mandrels are not needed for assembly of

fittings using hand tool method.

Caution

: Do not salvage used hose. Used hose is defined

as hose which has been removed from an installation and

returned for replacement.

A. Straight Swivel Fittings —

Step 1. Cut hose. Determine hose cut-off length

by subtracting cut-off factors from Table IV

from the desired hose assembly length.

Cut hose squarely. A hose cut-off wheel

is recommended. To prevent a flare-out of

the wire end during the cut-off operation,

several layers of tape should be wrapped

around the hose at the cut-off point. After

the hose is cut, and before proceeding with

the assembly, the tape may be removed.

Caution:

Hold hose firmly against angle

plate or bolts of cut-off machine to bend

hose at cutting point. It is recommended

that the operator cut one sample and check

length before proceeding with cutting the

required quantity.

Figure 12. Cut-Off Factors

NOTE:

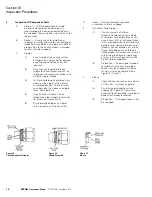

Cut-off factors are for one end only (see Figure 12). Add cut-off factors for

each end together and subtract from the desired hose assembly length to find the

correct hose cut length.

37º Flared Fittings

Size

Dim A

ST

Dim B

45º

Dim C

90º

-4

.92 (23.36)

2.06 (52.32

1.69 (42.92)

-6

1.04 (26.41)

2.35 (59.69)

1.92 (48.76)

-8

1.16 (29.46)

2.61 (66.29)

2.10 (53.33)

-10

1.21 (30.73)

2.74 (69.59)

2.06 (52.32)

-12

1.27 (32.25)

3.06 (77.72)

2.40 (60.95)

Flareless Fittings

Size

Dim A

ST

Dim B

45º

Dim C

90º

-4

1.69 (42.92)

2.79 (70.86)

1.69 (42.92)

-6

1.80 (45.72)

3.13 (79.50)

1.92 (48.76)

-8

2.14 (54.69)

3.55 (90.16)

2.10 (53.33)

-10

2.35 (59.69)

3.83 (97.28)

2.06 (52.32)

-12

3.70 (93.98)

4.38 (111.25)

2.40 (60.95)

Table IV Hose Cut-Off Factors

Dimensions shown in inches (mm)