Section X

Installation of Hose Assemblies

16

EATON

Aerospace Group

TF100-63B October 2018

C.

Installation with Bending — When bends are

required, the radii shown in Figure 23 should

be maintained for normal installation with

no flexing. A larger radius than the minimum

allowed is preferred.

D.

Flexing Installations — The following precautions

will help prevent kinking:

(1)

Hose should be bent in same plane

as movement to avoid twisting. See

Figure 24.

(2)

Hose flexing in two directions should

be clamped at the point where the

hose changes planes. (This has effect

of dividing hose into sections, each in

one plane.) See Figure 24.

3.

Torque Values, Installation

Swivel Connections — Install flared and Aeroquip

Globeseal flareless swivel connections using position-

tightening procedure as follows:

Step 1. Locate assembly in desired position and then

turn nut finger tight.

Step 2. While restraining nipple hex with one wrench,

tighten nut to the appropriate torque value in

Table VII.

Do not overtighten.

Step 3. If connection leaks during pressure check,

loosen and completely disconnect the nut.

Inspect the fitting for damaged sealing

surfaces, present of foreign material or

damage from previous overtightening.

Figure 23. Minimum Bend Radius.

Figure 24. Flexing Installations.

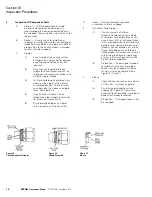

Fitting

Size

Torque in. - lbs.

Steel

Min.

Max.

-4

135

145

-6

215

245

-8

430

470

-10

620

680

-12

855

945

Hose

Size

Recommended

Min. Bend Radius

inches (mm)

-4

1.50

-6

2.50

-8

2.88

-10

3.25

-10

3.88

Installation Torque Values, Flared and Globeseal Flareless Swivel Fittings

4.

Fittings Used On Aeroquip AE246 Hose

In addition to the above general procedures, the

following caution should be observed.

Caution:

Do not place wrench on socket of hose fitting

when installing hose lines.

Table VII