Section X

Installation of Hose Assemblies

EATON

Aerospace Group

TF100-63B October 2018

15

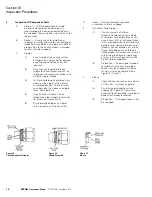

Figure 22. Routing and Clamping of Hose Lines

1.

Installation, General

Extra care should be exercised to avoid kinking

as a result of sharp bending or twisting.

Caution:

Kinking occurs more easily in larger

size hose and in very short hose lines. Use

care in handling and installing all PTFE lines.

Note:

Wires and clamps used to hold pre-

formed shapes should be removed at time of

installation.

2.

Routing And Clamping

All hose lines must be carefully routed and

securely clamped to avoid abrasion and particu-

larly to prevent kinking on flexing installations.

Figure 22 illustrates routing and clamping of

hose lines.

A.

Protection Against Abrasion — Eliminate

chafing against structure, moving parts

of other lines by proper clamping and

by use of chafing guard on unsleeved

hose assemblies (Aeroquip 656 PTFE

Guard or 646 Neoprene Chafe Guard), if

necessary.

B.

Hose Line Support — Support hose at

least every 24 inches. Closer supports

are preferred. Flexible liens should

be supported so that they will not

cause deflection of rigid connecting

lines. Hose lines between two rigid

connections may have excessive motion

restrained where necessary but should

never be rigidly supported. Support

clamps shall not restrict travel or

cause hose to be subjected to tension,

torsion, compression or shear stress

during flexing cycles. Select proper size

support clamp from Table VI.

Hose Dash Size

-4

-6

-8

-10

-12

High Pressure AE246

MS21919-

6

8

10

12

14

High Pressure AE246

with AE102 Fire Sleeve

MS21919-

11

14

16

17

19

Note:

Appropriate clamp cushion material to be determined by application conditions.

Table VI

Cushion support clamp sizes (for use with Aeroquip AE256 hose)