Programming

Operating Instructions 755 B, 756 B/F - 00.0 - 02/2021

267

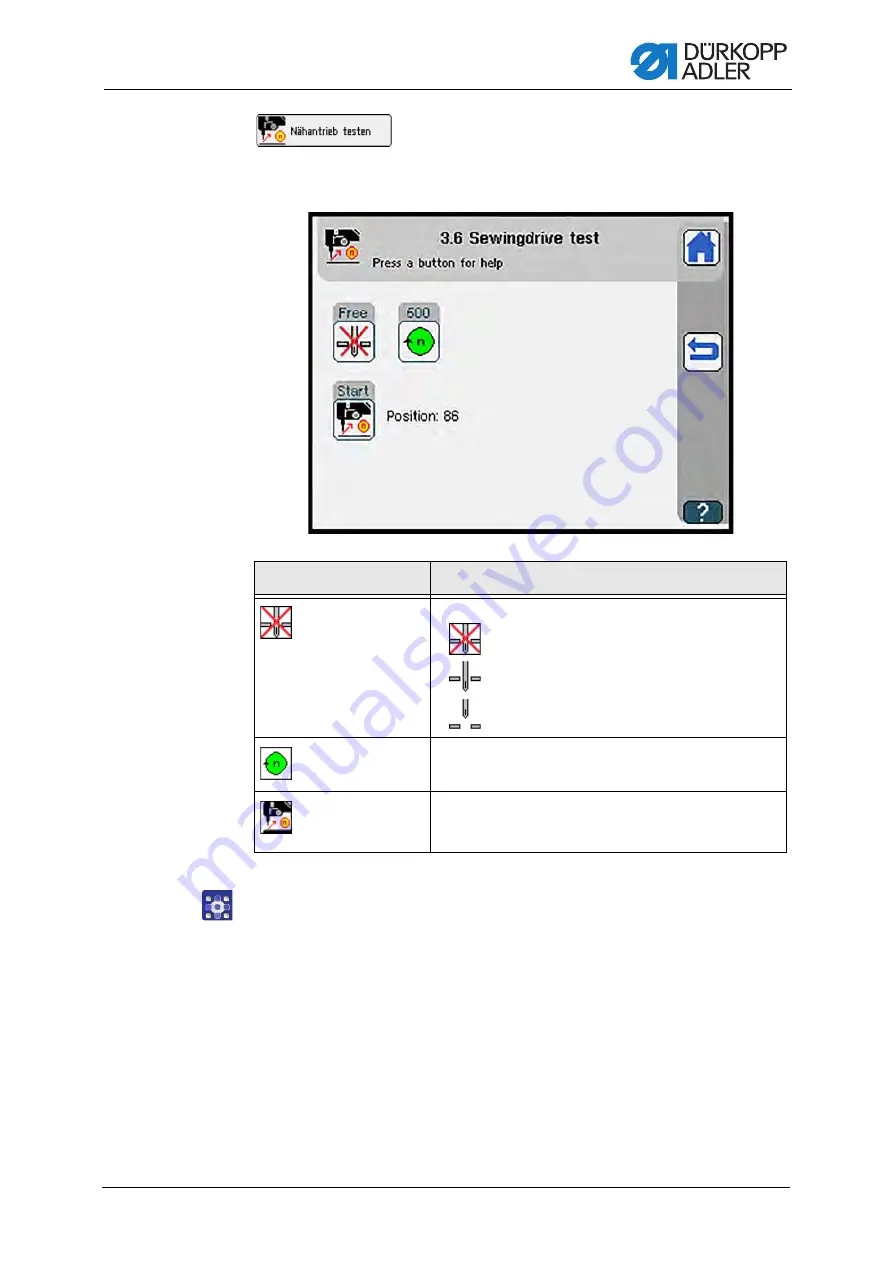

Sewing drive test

The display switches to

Sewing drive test

.

Fig. 219: Sewing drive test

To test the sewing drive:

1. Press the desired button.

2. Enter the desired values using the numeric keypad.

3. Confirm with

OK

.

Symbols

Meaning

Select needle position

•

Needle not positioned

•

Needle down

•

Needle up

Adjust speed

• 70 RPM - 3000 RPM

Start sewing drive

• Indicated position: Value of the motor setpoint device

(exact motor position)

Summary of Contents for 755 B

Page 1: ...755 B 756 B F Operating Instructions...

Page 6: ...Table of Contents 4 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 10: ...About these instructions 8 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 18: ...Machine description 16 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 292: ...Programming 290 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 306: ...Maintenance 304 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 328: ...Setup 326 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 330: ...Decommissioning 328 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 332: ...Disposal 330 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 354: ...Technical data 352 Operating Instructions 755 B 756 B F 00 0 02 2021...

Page 373: ......