2

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

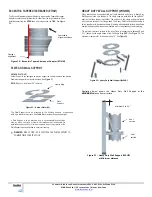

SECTION B - GENERAL INFORMATION

PART NUMBERS

These instructions identify major model parts by name and part number.

Example:

DIS1 - 36” length with inside diameter 14” made of 316SS flue (inner w a l l ) and

304SS (outer casing).

DIS1 14

L36 BC

Model

Dia. Part Material Type

DAS1 - 30° elbow with inside diameter 22” made of 30SS flue (inner wall)

and galvalume (outer casing).

DAS1 22 E30

CE

Model

Dia. Part Material Type

DCL - single wall support for 8” diameter grease duct made of galvalume.

DCL 8 WS

E

Model

Dia Part

Material Type

Use only factory-supplied components. Failure to do so will void the

certification and the warranty of the grease duct system.

EFFECTIVE LENGTH

The effective length is the length of the part when it is assembled.

Effective length

L36 ................36 1/16”

L24 ................24 1/16”

L18 ................17 9/16”

L12 ................11 9/16”

CLEARANCE

DuraVent Models D C L , D A S - P R O a n d D I S - P R O are primarily intended to be

used in a non-combustible surrounding. Only Models DAS-PRO and DIS-PRO can

be used for either combustible or non-combustible surroundings. When installed

in an open room where enclosure is not required, the chimney may be located

at a minimum clearance to adjacent combustible walls in accordance with Table

1. The chimney may be located in corners formed by two combustible

constructions (walls, floor, ceiling, supports, etc.)

NOTE: The clearance distance with the wall is the distance between the wall and

the inner V-Band for model DCL or the Outer Band (BSE) for model DAS-PRO and

DIS-PRO. See

Table 1

for the clearance distance.

For non-combustible construction, maintain clearance as required for installation

access for inspection or per local code. In buildings more than one story in height

and in one-story buildings where the roof-ceiling assembly is required to have a fire

resistance rating, the duct must be enclosed in a continuous enclosure from the

lowest fire-rated ceiling or floor above the hood, through any concealed spaces,

to or through the roof to maintain the integrity of the fire separations required

by the applicable building code provisions. If the building is less than 4 stories

in height, the enclosure shall have a fire resistance rating of not less than 1

hour. If the building is 4 stories or more in height, the enclosure shall have a fire

resistance rating not less than 2 hours.

DuraVent models DAS-PRO and D I S -PRO chimneys may penetrate a combustible

floor, wall, or roof using the appropriate parts and openings sizes. See Section D

“Roof and Wall Penetration” for more details.

NOTE: Do not enclose with combustible materials

In the case of a fire rated enclosure made of non-combustible or limited

combustible construction, the minimum clearance with the Model

D

CL must

be 6” or as required by local code.

TABLE 1 –

Minimum Air Space CLEARANCE to

Unenclosed Combustible Surroundings

(adjacent to maximum of two [2] walls)

Vent Model

Flue Diameter Ø

(in)

Clearance to

Combustible

(in)

Clearance to

Non-

Combustible

(in)

DCL

5 to 36

18

0

DAS1

5 and 6

4

0

7 to 14

5

0

16 to 22

6

0

24 to 30

7

0

32 to 36

8

0

DIS1

(UL103 Type HT

5” to 24” only)

5 and 6

1

0

7 to 14

2

0

16 to 22

3

0

24 to 30

4

0

32 to 36

5

0

DIS2 &

DIS4

(UL103 Type HT

5” to 24” only)

5 to 14

1

0

16 to 30

2

0

32 to 36

3

0

Dimensions are in inches

OPENING

THROUGH

CONSTRUCTION

The following table serves to identify the minimum opening required

when installing a chimney through a floor, wall or roof made of

combustible material. See

Table 2.

TABLE 2 -

Openings in Floor / Wall / Roof – for ALL

MODELS

Vent

Model

Flue

Diameter

Ø

(in)

Combustible

Roof, Floor

or Wall

(in)

Non-Combustible

Roof / Floor / Wall

(in)

Installed Stacks

(locking Bands

Installed)

Uninstalled

Stacks ( NO

locking Bands

Installed)

DCL

5 to 36

ID + 37 – ¼”

ID + 2 – ½”

ID + 1 – 1/8”

DAS1

5 and 6

ID + 10 – ¾”

ID + 4 – ½”

ID + 2 – ¾”

7 to 9

ID + 12 – ¾”

10 to 14

ID + 3 – ½”

16 to 22

ID + 14 – ¾”

24 to 30

ID + 16 – ¾”

32 to 36

ID + 18 – ¾”

DIS1

5 and 6

ID + 4 – ¾”

ID + 4 – ½”

ID + 2 – ¾”

7 to 9

ID + 6 – ¾”

10 to 14

ID + 3 – ½”

16 to 22

ID + 8 – ¾”

24 to 30

ID + 10 – ¾”

32 to 36

ID + 12 – ¾”

DIS2

5 to 7

ID + 6 – ¾”

ID + 6 – ½”

ID + 4 – ¾”

8 to 14

ID + 5 – ½”

16 to 30

ID + 8 – ¾”

32 to 36

ID + 10 – ¾”

DIS4

5 to 7

ID + 10 – ¾”

ID + 10 – ½”

ID + 8 – ¾”

8 to 14

ID + 9 – ½”

16 to 30

ID + 12 – ¾”

32 to 36

ID + 14 – ¾”

Dimensions are in inches