10

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

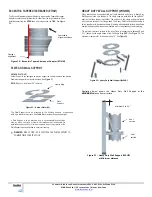

ELBOW OFFSETS

The following tables provide the MINIMUM offsets for the

various elbows

Table 8a, 8b, 8c and 8d

Figure 28 – MINIMUM OFFSET for ELBOWS

TABLE

8a

‐

Minimum

Offset

for

Each

Elbow

‐

DCL

Diameter

Ø (in)

3°

15°

30°

45°

90°

5

3/8

2

4

1/8

6

1/4

13

1/4

6

3/8

2

4

1/4

6

5/8

14

1/4

7

3/8

2

4

3/8

6

7/8

15

1/4

8

3/8

2

4

1/2

7

1/8

16

1/4

9

3/8

2

1/8

4

5/8

7

1/2

17

1/4

10

3/8

2

1/8

4

3/4

7

3/4

18

1/4

11

3/8

2

1/8

4

7/8

8

19

1/4

12

3/8

2

1/8

5

8

3/8

20

1/4

13

3/8

2

1/4

5

1/8

8

5/8

21

1/4

14

3/8

2

1/4

5

1/4

8

7/8

22

1/4

16

3/8

2

3/8

5

1/2

9

1/2

24

1/4

18

3/8

2

3/8

5

3/4

10

1/8

26

1/4

20

3/8

2

1/2

6

1/8

10

5/8

28

1/4

22

3/8

2

1/2

6

3/8

11

1/4

30

1/4

24

3/8

2

5/8

6

5/8

11

7/8

32

1/4

26

3/8

2

5/8

6

7/8

12

1/2

34

1/4

28

3/8

2

3/4

7

1/8

13

36

1/4

30

3/8

2

3/4

7

3/8

13

5/8

38

1/4

32

3/8

2

7/8

7

5/8

14

1/8

40

1/4

34

3/8

3

8

14

3/4

42

1/4

36

3/8

3

8

1/4

15

3/8

44

1/4

Dimensions

are

in

inches

TABLE 8b

Minimum Offset for Each Elbow -

DAS1 & DIS1

Diameter

Ø (in)

3° 15° 30° 45° 90°

5

1/2

2 1/2 5 1/4

8 1/4

18 1/2

6

1/2

2 1/2 5 3/8

8 1/2

19 1/2

7

1/2

2 5/8 5 1/2

8 3/4

20 1/2

8

1/2

2 5/8 5 3/4

9 1/8

21 1/2

9

1/2

2 5/8 5 7/8

9 3/8

22 1/2

10

1/2

2 5/8

6

9 5/8

23 1/2

11

1/2

2 3/4 6 1/8

10

24 1/2

12

1/2

2 3/4 6 1/4 10 1/4

25 1/2

13

1/2

2 3/4 6 3/8 10 1/2

26 1/2

14

1/2

2 3/4 6 1/2 10 7/8

27 1/2

16

1/2

2 7/8 6 3/4 11 3/8

29 1/2

18

1/2

3

7

12 31 1/2

20

1/2

3 7 1/4 12 5/8 33 1/2

22

1/2

3 1/8 7 5/8 13 1/8 35 1/2

24

1/2

3 1/8 7 7/8 13 3/4 37 1/2

26

1/2

3 1/4 8 1/8 14 3/8 39 1/2

28

1/2

3 1/4 8 3/8 14 7/8 41 1/2

30

1/2

3 3/8 8 5/8 15 1/2 43 1/2

32

1/2

3 3/8 8 7/8 16 1/8 45 1/2

34

1/2

3 1/2 9 1/8 16 3/4 47 1/2

36

1/2

3 1/2 9 1/2 17 1/4 49 1/2

Dimensions are in inches