15

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

SECTION G – TERMINATION

GENERAL

An upward discharge (such as with an Exit Cone or Open Top) provides the most

effective means of dispersing chimney gases into the atmosphere and away from

immediate surroundings. Such terminations however, will allow entry of rain

unless there is upward flow at high velocity. A Stack Cap is only partially effective

in excluding rain. Its effectiveness depends on chimney gas flow rate, raindrop

characteristics and wind velocity.

If rain is to enter the chimney, install a drain tee cap at the bottom of vertical run. Use

a “P” trap in the drain if the system is under positive pressure.

EXIT CONE (P-EC)

The Exit Cone is of double wall construction, with separable inner and outer

cones. The inner cone has a 28° included cone angle and is sized to increase outlet

velocity to 1.5 times chimney velocity. It attaches with a standard Inner V-Band to

the uppermost chimney pipe section. The outer cone is then pushed down into contact

with the inner cone, clamped to the outer pipe, and the gap between cones is sealed

with silicone. To prevent rain from reaching an appliance, this installation requires use

of a Drain Section (P-DS), drained Tee or both in the vertical chimney. It is

recommended to fasten (3) self-tapping screws around the bottom circumference of

the exit cone outer wall (120° apart) into the upper outer wall of the pipe section below.

Do not penetrate the inner wall.

RAIN CAP (RC)

NOTE: Stack Caps are not recommended for use with engine or turbine exhausts. The

Stack Cap combines partial protection against rain entry with low exit flow

resistance. (Resistance coefficient is roughly 0.05 velocity heads.) It is mounted to

the end of a standard pipe section by use of the standard V-Band. A Closure Ring is

provided as part of the Stack Cap so that the insulating air space is maintained

through the upper end of the chimney.

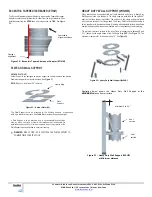

EXCESSIVE PRESSURE RELIEF VALVE (P-ER)

Excessive Pressure Relief Valves are intended to help control the venting of

pressure which may occur during an exhaust system backfire. Engines have the

potential to inject unburned fuel into an exhaust system during start up or due to an

engine malfunction.

This unburned fuel creates a condition where a backfire could occur. The Explosion

Relief Valve will help prevent damage to other parts such as Flex Connectors,

Silencers, Catalytic Converters, Convoluted Bellows and Heat Recovery Equipment.

Further precedence for use of Excessive Pressure Relief Valves can be found in

NFPA 37, “Standards for the Installation and Use of Stationary Combustion Engines

and Gas Turbines”. The Excessive Pressure Relief Valve should be located in the

beginning of the system and is supplied with bolts, washers, nuts, and gasket to

provide a complete gas tight connection to the 125/150 lb. ANSI flanged Flange

Adapter. The orientation of the Relief Valve should be positioned upright, as shown

Figure 42

for optimum performance.

MAINTENANCE OF ER VALVE IF USED OUTDOORS: It is RECOMMENDED to apply an

exterior grade high heat paint to the Guide Plate, Valve Seat, Valve Plate, and

Flange Adapter to ensure maximum corrosion resistance. (Ex. Rust-Oleum V200

series High Heat Industrial Aerosol) Caution: This device is designed to relieve

excessive pressure (27” W C with standard springs) in the case of an engine

malfunction for the sole purpose of protecting the physical integrity of the exhaust

system and related parts. If such malfunction occurs, the device will release hot

gases, sparks and/or flames into the immediate vicinity of the area it is located

in.

As such, this device should never be installed where human contact m a y

o c c u r d u e t o such release.

Excessive Pressure Relief Valve

Figure 42 – Excessive Pressure Relief Valve

GENERAL INFORMATION

M&G DuraVent reserves the right to make changes at any time,

without notice, in design, materials, specifications, prices.

Consult your local distributor for chimney system code

information.

WARRANTY

These products have a 15-year limited warranty. Please read the

warranty to be familiar with its coverage.

Retain this manual. File it with your other documents for future

reference.

PRODUCT REFERENCE INFORMATION

Please contact M & G D ur a Ven t for the phone number of your

nearest DuraVent dealer who will answer your questions or address

your concerns.

Further information may be obtained by visiting:

www.duravent.com

TOP