7

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

SECTION D-COMPONENTS

HIGH PRESSURE SYSTEM – up to 60” WC

THERMAL EXPANSION JOINT and ODD LENGTH

For Thermal Expansion we recommend using a Bellow Length (LB).

For ODD Length we recommend using a Variable Length (LV).

LOW PRESSURE SYSTEM – up to 6” WC

THERMAL EXPANSION and ODD LENGTH

For thermal Expansion and ODD Length we recommend using

an Adjustable Length (LA).

THERMAL EXPANSION

The inner pipe of Model DAS-PRO and DIS-PRO is load bearing and its thermal

expansion is the same as that of a continuous pipe. A simplified rule for exhaust

pipe expansion estimation is that the axial growth will be approx. 1” per 100’ of

pipe length for each 100°F the flue gas temperature is above the surrounding air

temperature.

See Thermal Expansion Formula on page 3.

When assembled in any orientation, the amount of thermal expansion of the inner

pipe is directly dependent on the inner wall temperature and the length of pipe

between fixed points. Good installation practice requires that expansion greater

than 1/4 inch will be compensated for using a Bellows Joint or Adjustable Length,

depending on the maximum pressure encountered.

The flanged inner piping joints have negligible flexing capacity, and in addition, tees

and elbows are not designed to withstand bending moment forces. Because the

amount of outer casing axial movement is the same as inner casing movement, the

outer jackets of piping must slide to avoid excessive forces on Tees, Elbows of fixed

points. To accommodate outer casing movements, external guides along walls at

floors or in lateral breechings must allow for movement of pipe.

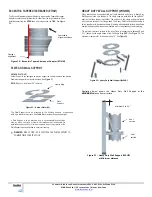

BELLOWS LENGTH

For exhaust pressure to 60 inches of water column, Bellows are recommended

for expansion and vibrational movements of the piping.

The Bellows has a 0.035” thick or heavier straight stainless steel liner to

protect the thinner spring material from heat and flow effects. It is used anywhere in

a system for axial and vibrational movements only and must be accurately

supported and guided. This part has limited lateral movement (1/8” max.) and

lateral offsets and parallel misalignments should be eliminated. The purpose of the

liner is to minimize contact, smooth flow, control erosion and eliminate resonance

caused by exhaust gases passing through the bellows.

See Table 7 for Bellows

Properties

Typical Bellow design

ADJUSTABLE LENGTH (LA) - EXPANSION JOINT

The

LA

has two functions. It is used to compensate for thermal expansion and

make up odd lengths of vent..

It is shipped with graphite band assembly preassembled on the sliding inner pipe.

The

LA

is adjustable from 7 1/4 to 28 3/8 inch.

See Figure 15

Figure

15

–

Adjustable

Length

(LA)

Gas

Flow

Cuttable

half

siding

outer

casing

Moveable

gasket

assembly

Cuttable

sliding

inner

wall

Spacing

Tool

supplied

Wrench

–

by

others