12

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

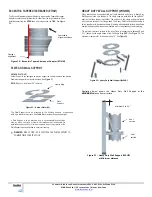

ECCENTRIC TAPERED INCREASER (ETINØ)

The Eccentric Tapered Increaser Adapter is similar as the Tapered Increaser

Adapter except the smaller diameter is offset from the larger diameter. When

installed horizontally, the

ETINØ

keep a flat slope unlike the

TINØ

. See

Figure

30.

Figure 30 – Eccentric Tapered Increaser Adapter (ETIN Ø)

PLATE AND WALL SUPPORT

ANCHOR PLATE (AP)

Anchor Supports are designed to provide support to vertical sections and provide

fixed-point support for horizontal sections. See

Figure 31

NOTE:

Rings a r e installed at 90° to plates.

Figure

31

–

Anchor

Plate

(AP)

The Plate Support must be attached to the building structure or supported

with rigid structural members. See

Table 4

for maximum supported height.

A Plate Support is to be attached only to non-combustible construction

such as block, concrete or steel with clearance that is adequate for

installation and access. For maximum support, the entire perimeter of the

Plate Support must be attached to structural framing.

WARNING:

RISK OF FIRE - DO NOT ATTACH THE PLATE SUPPORT TO

COMBUSTIBLE CONSTRUCTION

HEAVY DUTY WALL SUPPORT (WSHD)

When attached to a non-combustible wall with brackets and struts, a Heavy Duty

Wall Support makes up a fixed-point. The clamp rings are installed with the splits 90°

apart so that they support each other. The notches in the clamp rings are aligned

with the draw screws of the flange band. The Heavy Duty Wall Support Assembly is

bolted together with provided hardware. It is made with adjustable struts, which allows

a variable clearance from the non-combustible wall to the grease duct outer casing.

The minimum clearance varies with the size of the wall support, but is between 2 and

2 ½” (based on the angle shape of the Full Angle Ring (

FAR

). See

Figure 33.

The

maximum clearance for all sizes is around 10”. See

Figure 34

Figure

32

–

Heavy

Duty

Wall

Support

(WSHD)

Illustration below shows the Heavy Duty Wall Support at the

MINUMUM

distance from structure

Figure 33 – Heavy Duty Wall Support (WSHD)

at Minimum distance

Removable

Alignment

Sleeve

Clamp

Ring

Plate

Support

Minimum

2

to

2

½”

Vent

section

Vent

section

Straight

alignment