14

S

UBMITTAL

R

ECORD

FOR

D

URA

S

TACK

M

ODELS

DCL,

DAS1,

DIS1,

DIS2

AND

DIS4

M&G

D

URA

V

ENT

|

10

J

UPITER

L

ANE

|

A

LBANY

,

N

EW

Y

ORK

www.duravent.com

SECTION E – GUIDELINE FOR LOCATION OF

SUPPORTS

Supports can be used in different combinations to secure the

duct in place.

ADJUSTABLE, VARIABLE and BELLOW LENGTH

To prevent the LA, LV or LB from sagging, it is recommended

that the chimney section adjacent to the LA, LV or LB is

supported or guided.

When necessary, properly guide an adjustable length (LA) by

installing a Heavy Duty Wall Guide (WGHD) or any support

immediately below the chimney joint on the adjacent section.

TEE SUPPORT

The Tees must be properly supported to protect them from

bending forces. It can be done by means of an Anchor Plate

(AP), Anchor Plate Length (APL) or Heavy Duty Wall Support

(WSHD). When a Tee is used at the base of the vertical

riser, the preferred location for the support is above the Tee,

thus suspending the Tee.

ELBOW SUPPORT

Elbows are to be supported on one end with either an Anchor Plate

(AP), an Anchor Plate Length (APL) or a Heavy Duty Wall Support

(WSHD).

THROUGH FLOOR / CEILING SUPPORT

Supports for chimney that penetrate a non-combustible floor are to

be positioned on the top side of the floor. Include supports as per

the height limits in Table 3 and use either an Anchor Plate (AP) or

an Anchor Plate Length (APL) installed above structural framing

members.

THROUGH WALL SUPPORT

Chimney that penetrates a wall should be supported on both side

of the penetration. It can be supported by bracing with a Half

Angle Ring (HAR), an Anchor Plate (AP) or an Anchor Plate Length

(APL).

SECTION F – ROOF PENETRATION and FLASHINGS

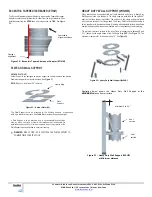

Flashing (F)

The flat Roof Flashing (F) is used in conjunction with Storm Collar

(SC) for weatherization on a flat roof.

Figure 39 – Flat Roof Flashing (F)

Storm Collar (SC)

The storm collar is installed above the opening of the flashing and

clamps to the outside of the vent. The top of the storm collar

should be sealed using S-375

Figure 40 – Storm Collar (SC)

Adjustable Flashing (F30)

The Adjustable Flashing (F30) is used in conjunction with Storm

Collar (SC) for weatherization on a flat roof with a 5 degree to 30

degree pitch.

Figure 41 – Adjustable Flashing (F30)

GUYING AND BRACING

1. Proper guying and bracing is essential for part of the Chimney that

extends above the roof or parapet wall. The grease duct at this point is

subject to wind conditions and needs special attention for proper

stabilization.

2. If the chimney above the roof does not exceed dimension H, no special

guying or bracing is required. However, to protect the flashing from lateral

movement, a guide must be installed at the roof level.

3. For chimney height above the roof that needs guying or bracing, a

support, a small length and a expansion length must be installed near the

roof level to absorb the thermal expansion and minimize this effect on the

guy wires or brace.

4. When using guy wire, the cable must be slightly slack or loose to allow

thermal expansion.

5. When using rigid bracing, the maximum vertical height between

supports must be reduced to 5’ to compensate thermal expansion.

Guy Section details and cable attachments

Seal

at

vent

with

S

‐

375