22

Dräger Polytron 8000

Settings menu

Displaying the Unique Identifier

This function enables reading of the Unique Identifier (unique

HART address), which has to be known for almost all the

HART addressing commands. However this information is only

required for those systems that are not able to read back the

Unique Identifier using HART command #0 in Short-Frame

Format or HART command #11. The display corresponds to

the address for HART command #0 (Read Unique Identi

fi

er) or

#11 (Read Unique Identi

fi

er associated with Tag).

z

Select

Settings > Communication > HART interface >

Unique Identifier

and confirm.

The Unique Identifier is displayed.

Changing the tag name

The tag can be used to identify special devices. It can contain

up to 8 alphanumeric characters. The tag can also function as

an address for reading the unique identifier from the device

using HART command #11 (Read Unique Identifier Associated

With Tag), even when the polling address is unknown.

This requires that a unique tag has previously been configured.

1. Select

Settings > Communication > HART interface >

Tag

and confirm.

2. Select the tag line for the entry and confirm.

3. Set the tag and confirm.

4. Select

Confirm

and confirm.

Selecting Dräger REGARD

This function enables switching between different HART

protocols.

1. Select

Settings > Communication > HART interface >

Dräger REGARD

and confirm.

2. Select

REGARD SW 2.0

or

REGARD SW 1.4

and confirm.

8.3.2

Settings for the analog interface

The test and setting functions for the analog interface are

summarized in this menu.

Setting the fault current

This function is used to set the current for the fault signal on

the analog interface.

1. Select

Settings > Communication > Analog interface >

Fault current

and confirm.

2. Select the fault current line and confirm.

3. Set the current and confirm.

4. Select

Confirm

and confirm.

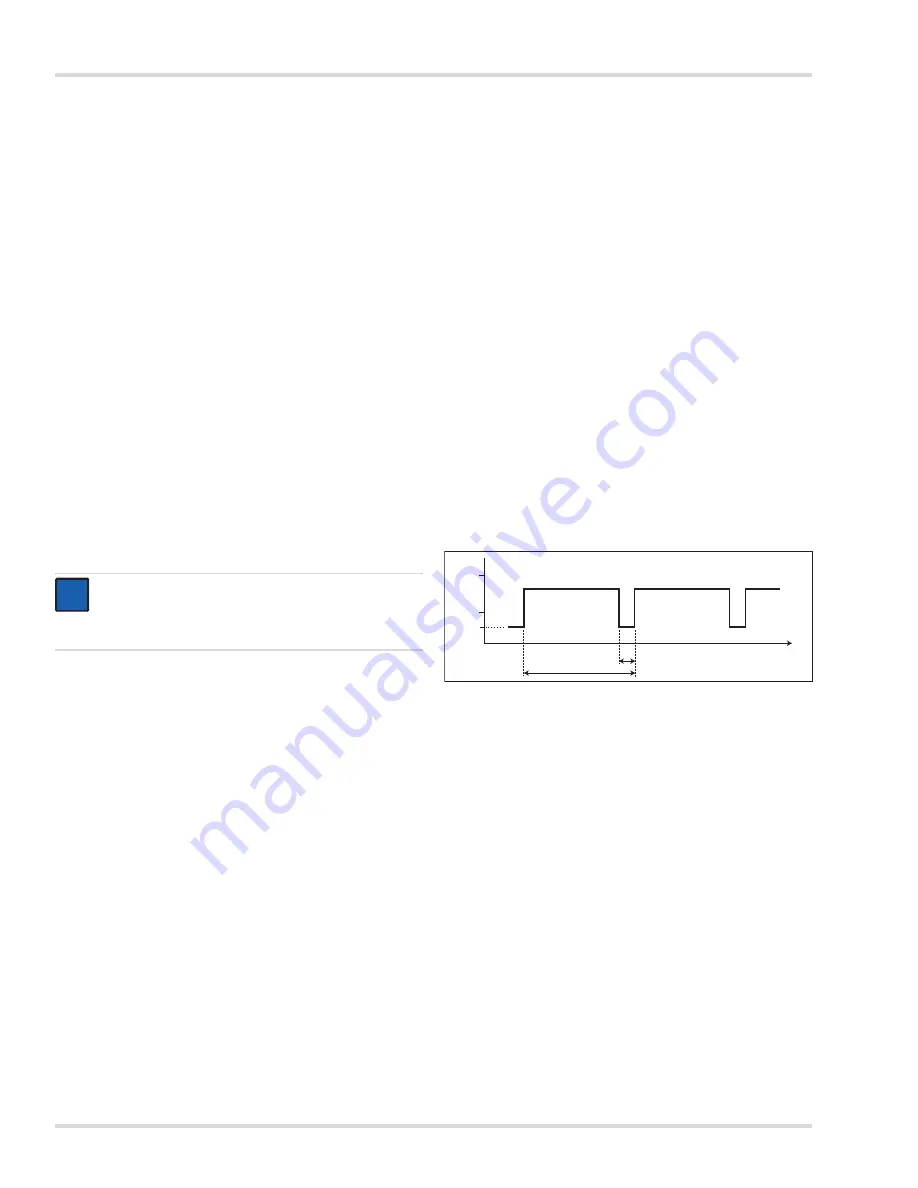

Switching the warning signal on or off

This function is used to switch the warning signal on the analog

interface on and off. If an existing warning is to be output over

the analog interface, the warning signal must be turned on.

During a warning, the current on the analog interface is switched

to the "Warning" status for one second. The measurement is

transmitted for the rest of the time. The interval between warning

signals and the analog signal phase can be customized.

To switch the warning signal on or off:

1. Select

Settings > Communication > Analog interface >

Warning

and confirm.

2. Select

On

or

Off

and confirm.

Setting the warning interval

This function is used to set the interval between the warning

signals and the measured value output.

1. Select

Settings > Communication > Analog interface >

Warning interval

and confirm.

2. Select line

T1

for the entry and confirm.

3. Set the time and confirm.

The setting for Time T1 is displayed.

4. Select

Next

and confirm.

5. Select line

T2

for the entry and confirm.

6. Set the time and confirm each setting.

The setting for Time T2 is displayed.

7. Select

Confirm

and confirm.

Setting the warning current

This function is used to set the current for the warning signal

on the analog interface.

1. Select

Settings > Communication > Analog interface >

Warning current

and confirm.

2. Select the current line for the entry and confirm.

3. Set the current and confirm.

The setting for the warning current is displayed.

4. Select

Confirm

and confirm.

Changing the maintenance signal type

This function sets the type of signal used on the analog

interface for the maintenance signal.

1. Select

Settings > Communication > Analog interface >

Maint. signal

and confirm.

2. Select

static

or

dynamic

signal type and confirm.

NOTICE

REGARD SW 2.0 is the standard setting. REGARD

SW 1.4 must be set on REGARD controllers with

SW 1.4.

i

i

0533300.eps

t

[s]

T

1

Messwert

4

20

[mA]

T

2

3

Value