12

Exit Device Operators 630/750/79E/RT/E7900 Series/ Generation E-730 PK3677_T

10-18

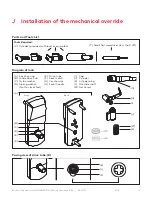

G Operating the emergency override

For RT lock series,

please refer to system 6000 manual. For multihousing refer to RezShield manual.

(Continued)

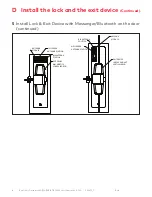

H Test the operation of the 630 lock

(For 730/750/79E lock go to Section E)

Communication Successful

Press any key to continue

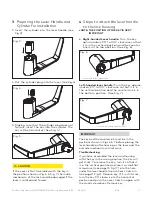

7. Open the door. You have only 4 seconds after

this message appears to open the door.

8. Remove the communication cable from the lock.

CAUTION

WARNING

IMPORTANT

If the lock will not respond to any keycard (includ-

ing the Emergency keycard), there are four options

that should be attempted to open the door. In

order, they are:

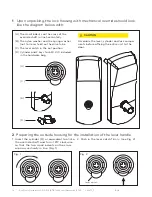

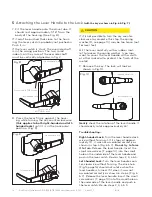

1 Panic Bar

Activate the panic bar. The latch bolt or rod

retracts fully.

2 Outside Lever

Turn the outside lever downward. The latch bolt

or rod does not retract.

If the latch bolt or rod retracts, verify that the

batteries are properly installed.

If the lever feels tight (hard to turn, or does

not return easily to its horizontal rest position),

check the spindle length vs. the door thickness

(the spindle may be too long). Check that the

slotted end of the spindle is inserted in the lock

housing hub, not the exit device.

3 Electronic

A Programming

Program the lock with at least one user, using

the Oracode Maintenance Unit. Generate a valid

code for this user. (Recommendation: generate

a code that starts a day before today and fin-

ishes at least one day after installation/testing

date, in order to avoid check-in/check-out time

periods)

B Code entry and access

Enter the user code to validate complete lock

operation. Verify that the green LED flashes at

each key pressed and a longer green LED flash-

es at the end of the code entry. Turn the outside

lever. Make sure the latch bolt retracts fully.

Release the lever, wait for the lock to return to

the locked mode (default settings is 5 seconds

after unlocking), and then turn the lever again.

The latch bolt must not retract after the lock

has returned to locked mode, which is typically

5 seconds (max 15 sec.) after unlocking, without

first entering a valid user code.