26

this is an energized circuit. Shock can occur

if not tested properly. testing is to be done

by a qualified service technician.

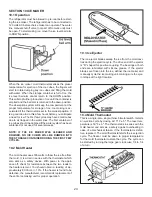

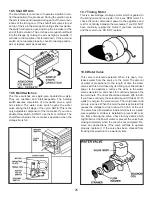

10.9 Ice maker replacement

It may be necessary to replace the entire ice maker as-

sembly. Disconnect power to the appliance. Disconnect

the 4 pin connector from the ice maker unit. Check each

wire for continuity to make sure the wiring is good before

replacing the ice maker unit. If there is no continuity on

any of these wires, replace or repair them as necessary

and recheck the ice maker unit to determine whether the

problem was in the wiring or the unit itself. Remove the

three screws holding the unit to the plate. Before replac-

ing the ice maker assembly check the temperature in the

freezer. For the unit to cycle it should be 12 degrees or

cooler as the mold thermostat starts the cycle.

10.10 Water fill adjustment

The correct water level in the mold is important for the

proper production of ice. The size of the ice cubes de-

pends on the amount of water which enters the mold. The

cubes should be approximately 1/2” wide, 3/4” high and 2-

1/2” long. If the water overflows in the mold, first check to

see if the ice maker unit is level in the appliance. Next en-

sure that the appliance is installed level in the RV. If there

is still water overflow, adjustment of the water fill screw is

necessary. Locate the screw on the ice maker assembly.

Turn the screw as necessary toward the “+” or “—” side.

One full turn of the screw will make an 18 cc change in

the amount of water. DO NOT turn the screw more than

one full turn at a time. If the water level is too high, it can

also cause the ejector blades to become frozen in the ice.

Follow the procedures above to correct the problem.

this is an energized circuit. Shock can occur

if not tested properly. testing is to be done

by a qualified service technician.

10.11 Water Supply

To operate properly, the water pressure in the water sup-

ply line must be between 15 and 50 PSI. Lower water

pressure, water turned off, or obstructions or air in the wa-

ter line can cause low or no ice production. First check to

see that the water supply is fully turned on. Visually check

the line for kinks, etc. which might obstruct the flow of

water. To remove trapped air, loosen the connection at the

water solenoid valve of the appliance. Ensure that pres-

surized water is reaching this point, and bleed off any air

in the line. Retighten the connection, making sure there

are no leaks.

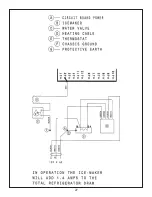

10.12 Wiring

Refer to the wiring diagram supplied with the unit you are

working on, and make sure all wiring connections are cor-

rect and tight. There are 4 wires coming from the ice maker.

BlacK:

Connected to incoming hot from AC pow-

er source. This could be split wire at the AC BLACK

at the circuit board or on a separate power cord.

WHIte:

Connected to either side of the water valve and

will split at the valve and hook-up to the incoming

WHIte

from the power source or separate cord.

green/yelloW:

Connected to chassis ground.

BroWn:

Connected to either side of water valve.

Summary of Contents for RM3962

Page 15: ...14 RM3762 RM3962...

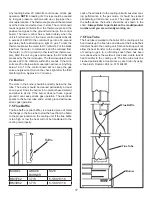

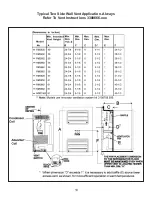

Page 20: ...19 Typical Two Side Wall Vent Application Always Refer To Vent Instructions 3308666 xxx...

Page 23: ...22...

Page 28: ...27...

Page 29: ...28 ICE MAKER TYPICAL WIRING DIAGRAM...

Page 33: ...32...