13

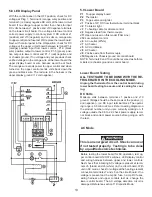

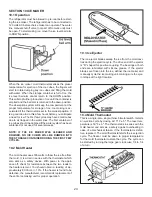

5.8 led display Panel

With the control panel in the OFF position, check for DC

voltage at Plug 1, Terminal 4 (orange wire) positive and

terminal 5 (red wire) negative DC volts at the lower circuit

board. If no voltage to upper control, then check for input

DC volts between J1 positive and J10 negative terminals

on the lower circuit board. If no voltage into lower control

correct power supply to control system. If DC volts at J1

(positive) and J10 (negative) and no volts on orange wire

to upper control and fuse test OK, replace the lower board.

Next, with control panel in the ON position, check for DC

voltage at the upper circuit board between terminal P1-4

(orange) positive input from lower control , P1-3 (black

wire) positive output to lower control, P1-5 (green) posi-

tive output to lower control and P1-1 (red) negative and

or chassis ground. If no voltage and your previous check

verified voltage on the orange wire at the lower board the

upper display board or wire harness would be at fault.

The orange wire sends power to upper control and when

turned on the upper control sends volts back down the

green and black wire. The red wire in the harness is the

upper display ground ( 12 volt negative) .

5.9 lower Board

P1

To upper display board

P2

Thermistor

P3

To gas valve and igniter

J1

Positive 12V DC from thermofuse / terminal block

J2

To interior light

J3

To heating cable for climate control

J4

Negative lead from thermocouple

J11

Open not used on this model (TAG Line)

J12

Low ambient control

J6

AC neutral (White)

J7

AC heater

J5

AC Hot (Black)

J8

AC heater

J9

Positive wire from thermocouple

J10

Negative to Chassis ground at control board

NOTE: Terminals 9 and 10 could be reversed as both ter-

minals are chassis ground on control board.

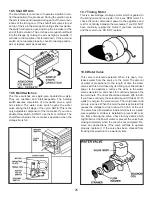

lower Board testing

all teStS are to Be done WItH tHe re-

frIgerator In tHe coolIng mode.

unplug the thermistor from the control board during

lower board testing to assure unit is calling for cool-

ing.

dc Volts

Measure volts between terminal J1 positive and J10

ground. Voltage should be the same as at the positive (+)

and negative (–) on DC input terminal block. The operat-

ing range is 9.6 min to 22 max. Refer to wiring diagram on

the product number unit you are currently working on. If

voltage outside the 9.6 to 22, check power supply, termi-

nal block and correct power source before going on with

the test.

ac mode

Before testing the lower board for AC operation, test up-

per control board ON/OFF switches, LED display control

and wiring harness between upper and lower controls.

Next check that incoming AC voltage is present at termi-

nals J5 (black) and J6 (white) on the circuit board. With

unit in AC mode, check for voltage at the heating element

connection terminals J7 and J8 on the circuit board. If no

voltage is present and 5 amp AC fuse, 3 amp DC fuses,

wiring harness and upper controls test ok, change the

lower control board. The AC voltage detection circuit is

damaged. Reference section 11 Dianostic Mode.

this is an energized circuit. Shock can occur

if not tested properly. testing is to be done

by a qualified service technician.

Summary of Contents for RM3962

Page 15: ...14 RM3762 RM3962...

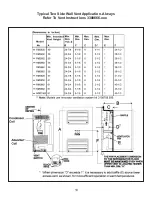

Page 20: ...19 Typical Two Side Wall Vent Application Always Refer To Vent Instructions 3308666 xxx...

Page 23: ...22...

Page 28: ...27...

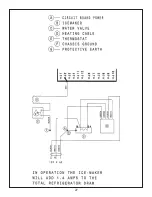

Page 29: ...28 ICE MAKER TYPICAL WIRING DIAGRAM...

Page 33: ...32...