15

gas mode

note: all current dometic control boards are

3 try systems in the gas mode. there is a

2 minute purge cycle between each trial for

ignition. flame failure could take 6 to 7 min-

utes.

Verify that the following components are good, upper cir-

cuit control boards, thermistor, wire harness and 3-amp

fuse. First, check for voltage during

trial-for-ignition

at

Plug 3, Terminals 1 (white Wire -) and 2 (yellow wire +) to

the igniter and solenoid. If no voltage is present change

the circuit board. If voltage is present, check for volt-

age at the igniter and solenoid. If no voltage is present,

check the wires. To check the flame sense circuit of the

lower circuit board, operate the refrigerator on GAS and

measure the millivolts between J4 (NEGATIVE) terminal

and J10 (POSITIVE) connection from the thermocouple.

The thermocouple should produce 20 millivolts minimum.

Anything less than 20 millivolts will cause erratic gas op-

eration. The millivolts meter should read between 25 to

35 millivolts with the gas flame burning. When the power

module senses the loss of flame (thermocouple millivolts

below 13 MVDC) the 45 seconds trial for ignition period is

started. Turning the refrigerator OFF–ON while operating

in the gas mode may cause a check light.

note: a loose ground will create erratic or

no gas operation.

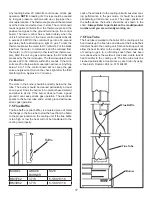

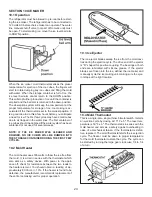

5.10 door Switch

The door switch is an open switch when the switch arm

is depressed (interior light should be off). When the re-

frigerator door is open the switch is closed (interior light

should be on). Check that the switch assembly is properly

aligned and that it is not broken. Check the switch assem-

bly for continuity. To do a continuity check, first be sure all

power is disconnected or OFF to the refrigerator. Second,

remove all wires from the switch assembly, then check the

switch. When the switch is depressed, there should not

be continuity. When the switch is NOT depressed, there

should be continuity. If any of these checks are incorrect,

replace the switch. After the check, be sure the switch as-

sembly is wired properly per the wiring diagram.

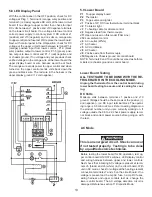

5.11 fuses

The 3 amp DC fuse is designed to protect the circuit board

from internal/external DC shorts. The 5 amp AC fuse is

designed to protect the integrity of the AC detection and

heater circuit from shorts. All fuses can be checked for

continuity. If a fuse blows don’t replace it until the problem

has been found. If a fuse blows there is a short or compo-

nent that has created the problem.

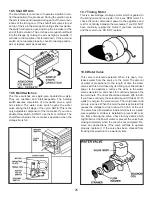

5.12 thermofuse

The RM3962/3762 cooling units have a Thermofuse lo-

cated on the boiler. The function of the thermofuse is to

shut down the control system in the event the cooling

unit over heats. On certain units the fuse can be reset

by pushing the button in the center. The thermofuse is a

non replaceable component of the cooling unit. When the

fuse pops it is normally an indication the cooling unit has

a problem and the cooling unit will have to be replaced.

The fuse can be checked for continuity.

Summary of Contents for RM3962

Page 15: ...14 RM3762 RM3962...

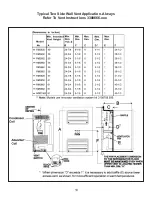

Page 20: ...19 Typical Two Side Wall Vent Application Always Refer To Vent Instructions 3308666 xxx...

Page 23: ...22...

Page 28: ...27...

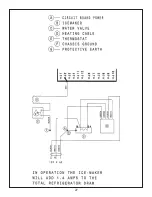

Page 29: ...28 ICE MAKER TYPICAL WIRING DIAGRAM...

Page 33: ...32...