17

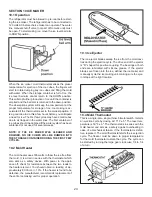

7.4 Burner

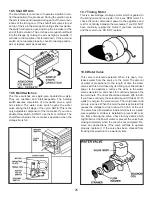

7.5 Flue Baffle

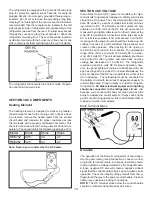

Any reading below 20 millivolts could cause erratic gas

operation.

note:

A reading of 20 or less could be caused

by low gas pressure, carbon build up or improper ther-

mocouple location. The thermocouple should be centered

over the burner and extend over 3 slots. The control board

reads negative millivolts from the thermocouple and the

positive lead goes to the ground terminal on the control

board. The lower control has a built-in delay when the

unit is first turned on. If the lower control reads millivolts

in excess of 6 MVDC the control will go into a 30 second

gas delay before attempting to light on gas. To test the

thermocouple set the meter to DC millivolts. Put the black

lead from the meter to terminal J4 and the red lead from

the meter to J10 or ground ( other lead from thermocou-

ple). Start the unit on gas and measure the DV millivolts

produced by the thermocouple. The thermocouple should

produce 22 to 36 millivolts within 45 seconds. If the milli-

volts are 20 or below erratic operation will occur. Anything

below 10 to 13 the control board will not keep the gas

valve energized and turn on the check light after the third

trial-for-ignition. Approx 6 to 7 minutes.

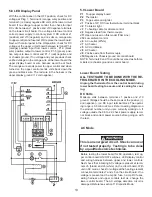

The slots in the burner should be directly below the flue

tube. The burner should be cleaned periodically, at least

once a year. Soak the burner in an alcohol based solvent

and allow to air dry. If the burner does not have a good

ground it can cause erratic gas operation. The electrode

sparks to the burner tube and a erratic ground will cause

erratic gas operation.

The flue baffle ( spiral baffle ) is a twisted piece of metal

that hangs in the flue tube to slow the heat from the flame

to the proper location on the cooling unit. If the flue baffle

is too high or low the heat will not be transferred to the

cooling unit properly.

MODEL

ABOVE

BURNER

SIZE

RM3762

1-7/8

5-1/8X13/16

RM3962

1-7/8

5-1/8X13/16

Lack of heat transfer to the cooling unit will cause low cool-

ing performance in the gas mode. It should be cleaned

periodically, at least once a year. The proper position of

the baffle above the burner should be as shown in the

chart :

always refer to parts list on the model/product

number unit you are currently working on.

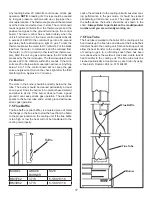

7.6 flue tube

The flue tube is welded to the boiler of the cooling unit. As

heat travels up the flue tube and slows at the flue baffle it

transfers heat to the cooling unit. Carbon build up will not

allow the heat transfer to the cooling unit and cause lack

of cooling on gas. In a ruff riding coach there has been

rare cases where the weld will crack and create lack of

heat transfer to the cooling unit. The flue tube must be

cleaned periodically, at least once a year. Clean by using

a flue brush, Dometic Part no. 0151404001.

Baffle

flue tube

Flue Baffle

Burner

Summary of Contents for RM3962

Page 15: ...14 RM3762 RM3962...

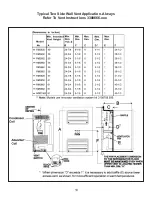

Page 20: ...19 Typical Two Side Wall Vent Application Always Refer To Vent Instructions 3308666 xxx...

Page 23: ...22...

Page 28: ...27...

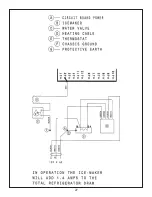

Page 29: ...28 ICE MAKER TYPICAL WIRING DIAGRAM...

Page 33: ...32...