21

4.

Air power feed option can be added to assist in

moving the workpiece through the saw band.

5.

The handle must be removed for saw band

changing.

HMD Hydraulc Table

1.

This factory-installed hydraulic-powered worktable

has a 36 inch (914.4 mm) or a 60 inch (1524.0 mm)

stroke instead of the standard table. The HMD-36

table's working surface is 34 by 42 inches (863.6 by

1066.8 mm). The HMD-60 table's working surface

is 34 by 68 inches (863.6 by 1727.2 mm).

2.

Information covering installation, operation and

maintenance of the optional HMD-36 or 60 table are

provided in a seperate instruction manual included

with the machine.

AIR-POWERED WORKTABLE

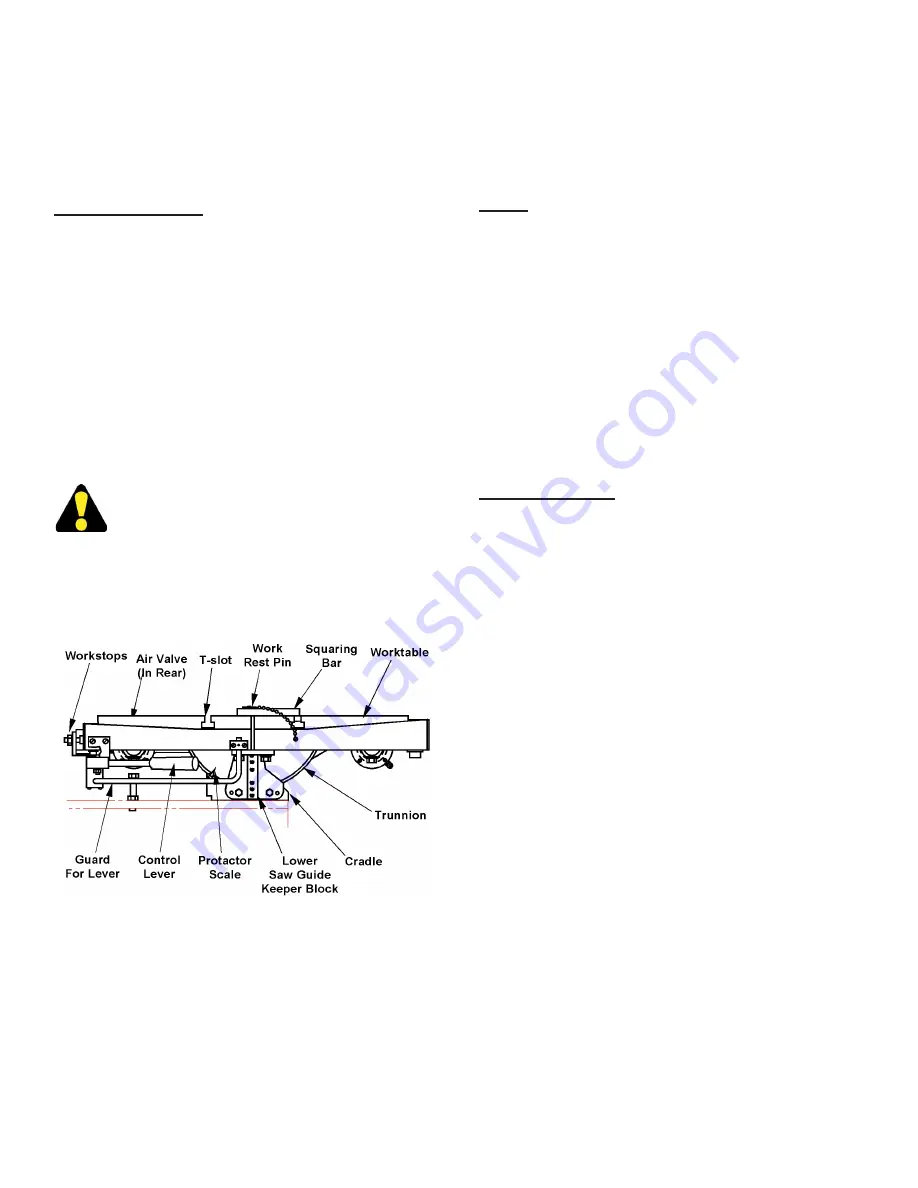

Ths attachment reduces the machne's work

heght capacty by one (1) nch (25. mm).

1.

This optional worktable provides a 24 by 30-1/2 inch

(609.6 by 774.7 mm) working surface with coolant

return troughs. The worktable can be tilted up to

6° left and 45° right when using this attachment. It

has two (2) T-slots for work fixture clamping.

Air-Powered Worktable.

2.

The worktable's air-amplified feed system is lever

controlled and allows 12 inches (304.8 mm) of

worktable travel. Light hand pressure against the

lever will move the worktable in forward motion.

Release the lever and pull back the worktable

manually.

3.

The worktable has a work rest pin that acts as a

workstop when inserted into the sawing slot. Other

worktable features are:

(a)

A squaring bar that fits

into a worktable T-slot to hold stockpieces during

production sawing;

(b)

Locks that permit the loading

and positioning of heavy stock;

(c)

Special center

plates for filing and polishing operations.

Set-Up

1.

Position the workstops located on the left side of

the worktable to limit travel. The front stop controls

cut depth; the rear stop minimizes unnecessary

travel. Stops are positioned by:

(a)

Loosening

the locknuts;

(b)

Sliding the stops to the desired

position; and

(c)

Tightening the locknuts.

2.

To tilt the worktable:

(a)

Use the wrench provided

to reach through the machine frame and under

the worktable to loosen the tilt locknut;

(b)

Tilt

the worktable manually until the pointer reaches

desired angle shown on the scale;

(c)

Tighten the

tilt locknut.

Producton Sawng

1.

Place the rest pin into the worktable's sawing slot to

serve as a workstop. Then:

(a)

Place the squaring

bar in the worktable's T-slot to act as the stock

holder.

Remove the rest pn and squarng bar

for contour sawng.

2.

Place stock on the worktable and secure it at the

desired position. Then:

(a)

Use the control lever to

carefully move the table forward until the saw band

has just started cutting into the workpiece;

(b)

Push

the control lever to obtain the desired feed force

(feed force will return to zero (0) when the lever is

released).

DBW-15 BUTTWELDER

1.

Information covering blade welding, plus operation

and maintenance of the optional DBW-15 Buttwelder

(with flash grinder and blade shear) are provided in

a seperate instruction manual.

OPTIONAL SAW GUIDE BLOCKS

1.

It is possible to equip the machine with precision,

heavy-duty, high speed, insert-type saw guides or

roller saw guides.

WORKTABLE OPTIONS (Continued....)