B-26

Procedures to install the power cable to the machine main body (Continued)

WARNING

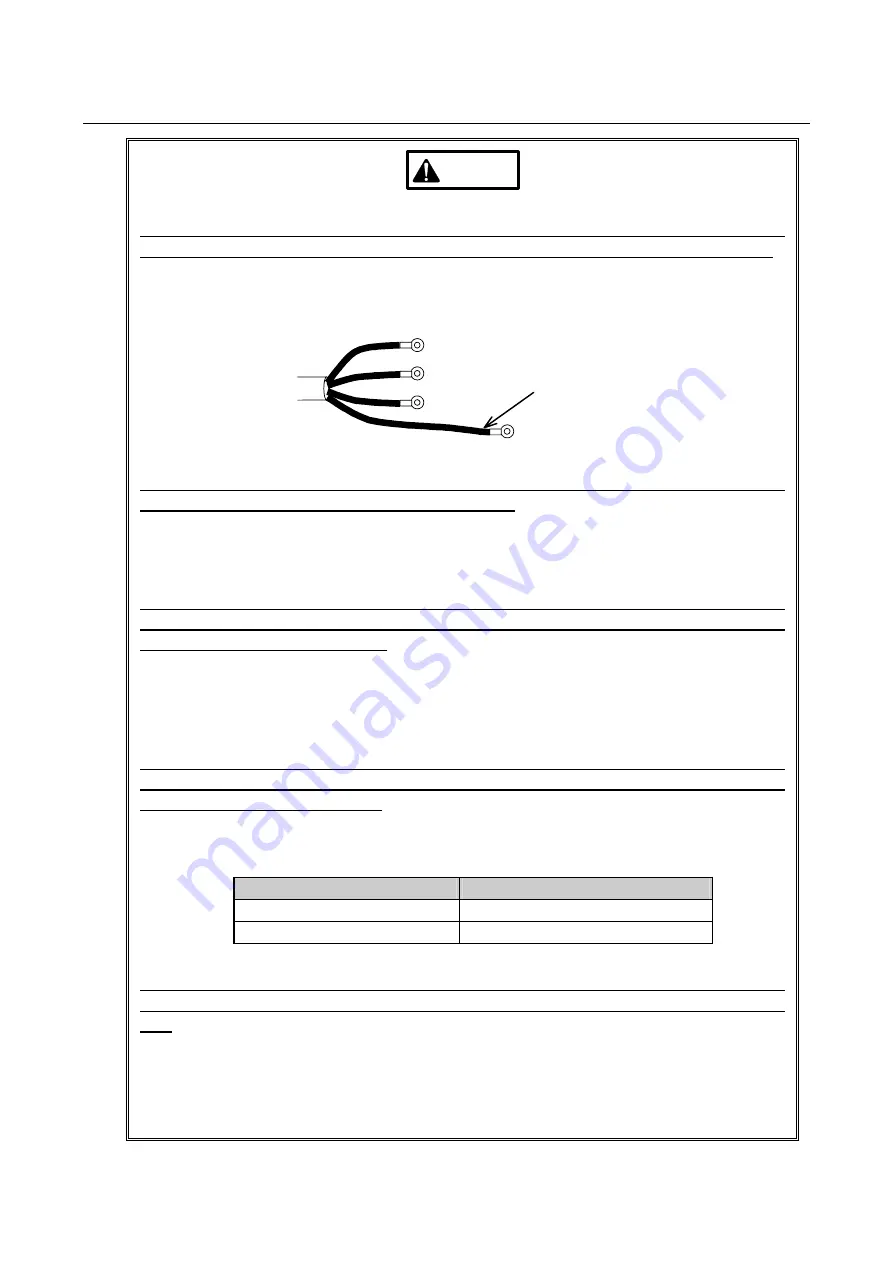

To prevent the PE line from being disconnected under the strain, make sure that

the PE line of the power cable is at least 300 mm longer than the L1/L2/L3 lines

If the PE line of the power cable is loosened or disconnected, you may receive an

electric shock from leaked current.

L1

L2

L3

PE

At least 300 mm longer

than the other lines

When installing the power cable to the machine, make sure to connect the PE

line of the cable first and confirm its connection

If you come into contact with the machine when it is not grounded, you may receive

an electric shock that could result in severe injury or death.

When a power cable is prepared by customers, a cable with the protective

conductor (PE wire) which has a cross-sectional area of at least 10 mm

2

Cu, or

16 mm

2

Al should be prepared.

Using a nonstandard power cable may cause an electric shock that could lead to a

serious injury or death. The power cable for this machine is prepared as an optional

accessory.

When connecting the power cable terminal to the power circuit breaker, be sure

to use a calibrated torque driver and tighten the screws of the breaker terminal

block with the specified torque

If the torque is not just enough, the connection between the power cable terminal and

breaker terminal block may heat up, which could cause a fire.

Where to torque

Tightening torque (N

•

m)

Breaker

3

PE 12.5

When the machine or floor is wet with water, do not touch the machine or wet

floor. Also, turn OFF the facility power source and lock it out with a padlock or the

like.

Also, never turn ON the facility power source until the machine and floor completely

dry. There is an electric hazard which could result in death or serious injury. Even

when the machine power is turned off, it will remain energized until the facility power

source is turned OFF.

Summary of Contents for DAG810

Page 85: ......