AIRCRAFT MAINTENANCE MANUAL

DFE-AMM-AR1

Rev. 1 – 07/24/2014

10-7

Application of smoothing layer

After preparation of mixture (for material recommendation see tab below) and its eventual

thickening to enhance the non curtaining capability (for vertical or lower areas) is performed its

application onto the repair area by means of a spatula. For better distribution of deposited

material on irregular surface it is possible to form it through the laid PE or PP transparent folia.

After proper application the layer is without bubbles. Deposit thicknesses given by necessary

thickness of surrounding layers (leveling) and ranges from 0.2 to 10 mm (0.0079 – 0.394 in) in

one deposit.

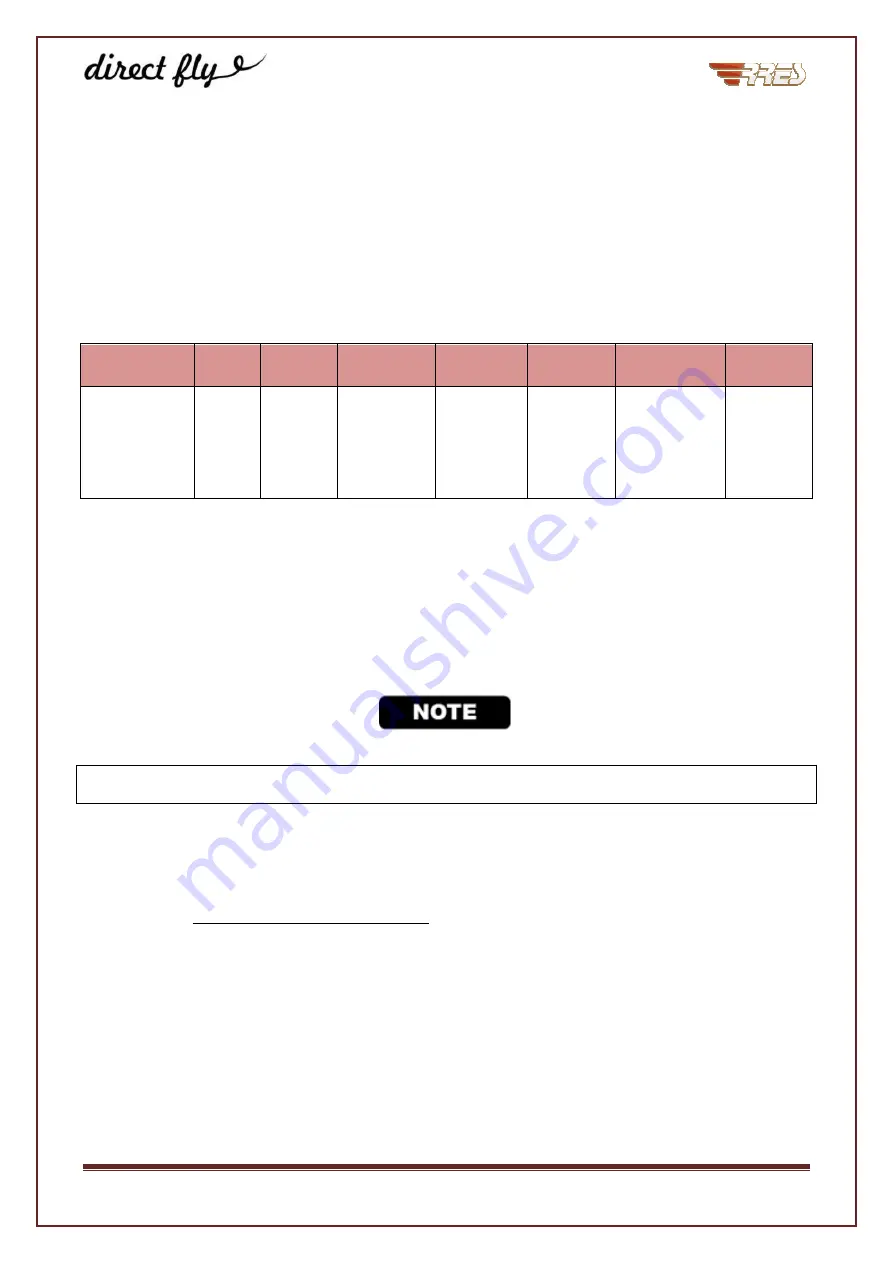

Recommended materials for mixture preparation for application of leveling layer

Manufacturer,

name

Type

Mixing

ration

Dwelling

Rate of

setting

Time of

setting

Temperature

Fillers

HUNTSMAN,

VANTICO,

Araldite 2011

(AW106 +

HV953U)

epoxy

A:B =

100:80

to be

processed

within

100min (for

0.1 kg

mixture)

40%

24 hours

(32hrs)

20 - 35°C

(17 - 20°C)

thickening:

Aerosil,

micro balls

Grinding

Grinding or eventually sealing the surface is made after setting the mixture and possible

tearing off the used folia. It is suitable to start grinding with grain size up to 160 and finish with

grain size of at least 400. It is carried out by dry grinding equipment with suction from the

grinding area. Al2O3 (fused corundum) can be used as grinding material. Basic material of

the part must not be diminished at grinding.

Especially in case of Carbon/Kevlar stiffener in the basic part, grinding through up to the stiffener must not

occur (complication - see note about preparatory grinding at medium damage).

Finishing

See Section 11 – Painting and Coatings..

•

Task proper accomplishment check: Visual check