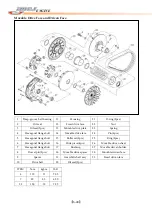

ENGINE

【

6-35

】

Piston

Piston

Diameter

●

Check

for

wear

and

damage

on

the

sliding

surface.

●

Measure

OD

of

Piston

at

the

position

shown

in

the

picture.

If

the

measurement

is

less

than

the

limit,

replace

the

piston.

Piston

OD

Service

limit

101.880

mm

Micrometer

(100

–

125

mm)

Recognize

Piston

●

The

top

of

piston

was

printed

“

A

”

and

“

B

”

.

●

A

Piston

has

to

be

matched

with

A

cylinder

;

B

Piston

has

to

be

matched

with

B

cylinder

.

Piston

Rings

Clearance

between

Piston

Ring

and

groove

●

Measure

the

clearance

between

Piston

Ring

and

groove,

by

holding

the

Ring

upwards

in

the

groove,

with

thickness

gauge.

●

If

any

of

the

clearances

exceeds

the

limit,

replace

both

piston

and

piston

rings.

Service

Limit

of

clearance

First

0.180

mm

Second

0.150

mm

Piton

ring

groove

width

Standard

First

1.21

‐

1.23

mm

Second

1.21

‐

1.23

mm

Oil

2.01

‐

2.03

mm

Piton

ring

thickness

Standard

First

1.17

‐

1.19

mm

Second

1.17

‐

1.19

mm

Thickness

Gauge

Micrometer

(0

–

25

mm)

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...