ENGINE

【

6-29

】

W

45

○

●

After

the

desired

seat

position

and

width

is

achieved,

use

the

45

○

cutter

slightly

to

clean

up

any

burrs

caused

by

the

previous

cutting

operation.

CAUTION

Do

not

use

lapping

compound

after

the

final

cut

is

made.

The

finished

valve

seat

should

have

a

velvety

smooth

finish

but

not

a

highly

polished

or

shiny

finish.

This

will

provide

a

soft

surface

for

the

final

seating

of

the

valve

which

will

occur

during

the

first

few

seconds

of

engine

operation.

●

Clean

and

assemble

the

head

and

valve

components.

Use

the

vacuum

pump

gauge

to

cover

intake

and

exhaust

ports

and

check

for

leaks.

If

any

leaks

occur,

inspect

the

valve

seat

and

face

for

burrs

or

other

things

that

could

prevent

the

valve

from

sealing.

NOTE

D004

‐

Vacuum

Pump

Gauge

After

servicing

the

valve

seats,

be

sure

to

check

the

valve

clearance

after

the

cylinder

head

has

been

reinstalled.

Valve

Spring

●

Measure

the

free

length

of

Valve

Spring.

●

Check

the

force

required

to

compress

the

spring.

●

If

the

result

is

not

correct,

replace

the

spring.

Service

Limit

of

Valve

spring

free

length

IN

&

EX

48.0

mm

Service

Limit

of

Valve

spring

free

length

IN

&

EX

19.0~21.4

kgf

/

36.50mm

Vernier

Calipers

Summary of Contents for DL-702 2008

Page 1: ...FOREWORD INDEX 0 0...

Page 41: ...3 11 BRAKE...

Page 180: ...6 70 ENGINE Install the starter motor...

Page 201: ...7 21 COOLING AND LUBRICATION SYSTEM Engine Lubrication System Chart...

Page 202: ...7 22 COOLING AND LUBRICATION SYSTEM Engine Lubrication System 1 2 3 1 2 3 1 2 3...

Page 203: ...7 23 COOLING AND LUBRICATION SYSTEM 1 2 3...

Page 235: ...7 32 ELECTRICAL SYSTEM Wiring Diagram...

Page 236: ...7 33 ELECTRICAL SYSTEM Wiring Diagram...

Page 237: ...7 34 7 34 ELECTRICAL SYSTEM ELECTRICAL SYSTEM...

Page 238: ...7 35 ELECTRICAL SYSTEM NOTE...

Page 240: ...9 2 PERIODIC MAINTENANCE...

Page 246: ...9 8 PERIODIC MAINTENANCE Intake Side...

Page 247: ...9 9 PERIODIC MAINTENANCE Exhaust Side Side...

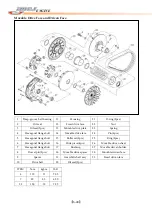

Page 270: ...9 32 PERIODIC MAINTENANCE 1 2 3 4 18 19 12 16 17 21 13 14 15 22 23 5 6 7 8 9 12 10 11 20...