CC7574DKV OPERATOR’S MANUAL

7. Place one of the removed setscrews into

the third setscrew hole (in line with slot) on

the bushing. Using a 1/2” impact wrench,

tighten the setscrew into the hole to

separate the sheave from the bushing. If

the sheave and bushing will not separate,

wedge a flat-head screwdriver into the slot

on the bushing and tap the other end of the

screwdriver with a rubber mallet to

separate the sheave and bushing.

8. Remove the sheave from the bushing.

9. Repeat steps 5–7 to remove the three

remaining sheaves.

10. Remove the setscrew used to separate the

sheave and bushing from all four bushings.

Installing Belt Sheaves

1. Fit the appropriate size sheave onto each

bushing.

2. On one side of the saw, place a

straightedge against the edge of the upper

or lower sheave. Adjust either sheave to

align the outside edge of both sheaves.

3. Place two setscrews into the setscrew

holes (in line with each other) on both

sheaves and retighten the setscrews to

secure.

Note: Make sure both sheaves are properly

aligned prior to securing.

4. Repeat steps 2–3 for the second set of

sheaves.

5. Reinstall both sets of belts on the sheaves.

6. Turn both blade drive belt tension bolts

(large threaded bolt on engine foot)

clockwise equally to tighten the belts. Test

the belt tension and readjust the bolts as

necessary. DO NOT exceed the

manufacturer’s tension settings.

7. Tighten the nut on both blade drive belt

tension bolts down to the engine foot.

8. Retighten the two engine cradle screws.

9. Close and latch the front hood assembly.

Blade Drive Belts

WARNING

•

Turn off the engine prior to servicing the

belts.

•

Use extreme caution when working with

belts and rotating machine parts to avoid

entanglement.

CAUTION

•

Let the belts cool down prior to servicing

them.

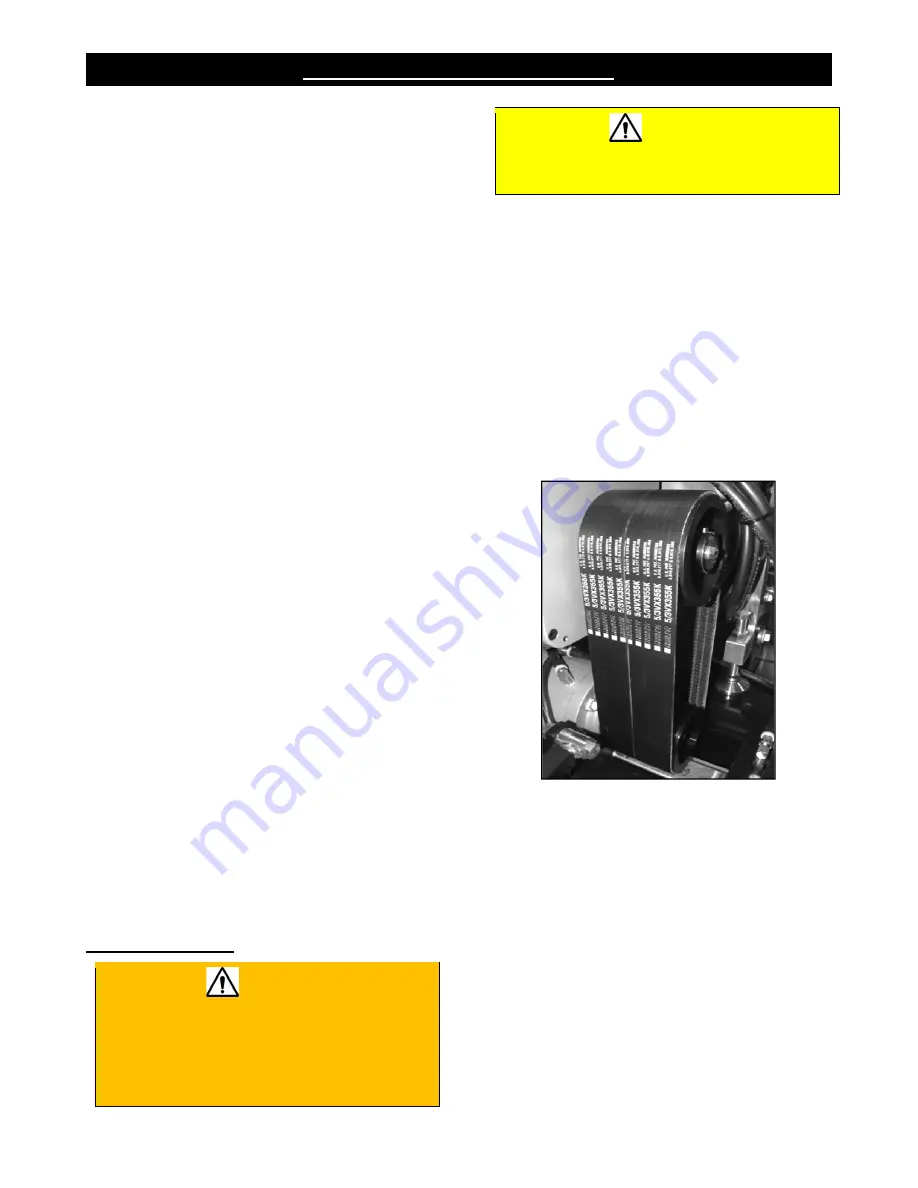

Inspect all belts daily for fraying, stress cracks,

and/or breakage and replace immediately

when damaged. Always re-tension new belts

after the first four hours of use. DO NOT

exceed the manufacturer’s recommended belt

tension settings when tensioning belts.

Note: Over-tensioning belts may reduce the life

of the gearbox bearings. Under- tensioning

belts may cause slippage, shorter belt life,

and/or poor saw performance. Squealing belts

indicate looseness.

Tensioning/Replacing the Blade Drive

Belts

Blade Drive Belts

1. Unlatch and open the front hood.

2. Test the belt tension.

3. Loosen the two engine cradle screws using

the 1-1/16” & 1-1/8” open end wrench

located on the left side of the saw near the

gearbox expansion tank.

4. If tensioning the belts, proceed with steps

9-12. If replacing the belts, continue with

steps 5-12.

5. Loosen the nut away from the engine foot

on both blade drive belt tension bolts using

the 1-1/16” & 1-1/8” open end wrench

6. Turn both blade drive belt tension bolts

(large threaded bolt on engine foot)

counterclockwise to loosen the belts.

59

Summary of Contents for CC7574DKV

Page 1: ...CORE CUT OPERATOR S MANUAL CC7574DKV CC7574DKV 3 MAY 2022 Part 1802742 01...

Page 2: ......

Page 11: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Specifications 11...

Page 12: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Specifications 12...

Page 65: ...CC7574DKV OPERATOR S MANUAL Appendix B CC7574DKV RPM Chart CC7574DKV 3 RPM Charts 65...

Page 66: ...CC7574DKV OPERATOR S MANUAL 66...

Page 67: ...CC7574DKV OPERATOR S MANUAL CC7574DKV Blade Size Conversion Chart 67...

Page 68: ...CC7574DKV OPERATOR S MANUAL CC7574DKV 3 Blade Size Conversion Chart 68...

Page 71: ......