For AL AC wires:

To make sure good conductivity, bi-metal adapter must be used in conjunction

with aluminum wires.

Extreme temperature rise at the clamping point

If the contact resistance between the aluminum conductor and clamping point is too

high, the clamping point can become very hot and even catch fire in extreme cases.

To ensure a safe and reliable contact,

always

perform the following work steps:

Use a conductor cross-section at least one number larger due to the lower

current-carrying capacity.

Keep the installation location as free as possible from moisture or corrosive

atmospheres.

Connect the aluminum cables quickly.

Mechanically clean the stripped end of the aluminum conductor (using for instance

a knife blade to scrape off the oxide layer). Then immediately dip the aluminum

conductor into acid-fee and alkaline-free (=neutral) Vaseline and directly crimp

the aluminum wire with bi-metal adapter.

Tighten the clamping screw in the clamping body with the maximum permissible

tightening torque.

NOTICE

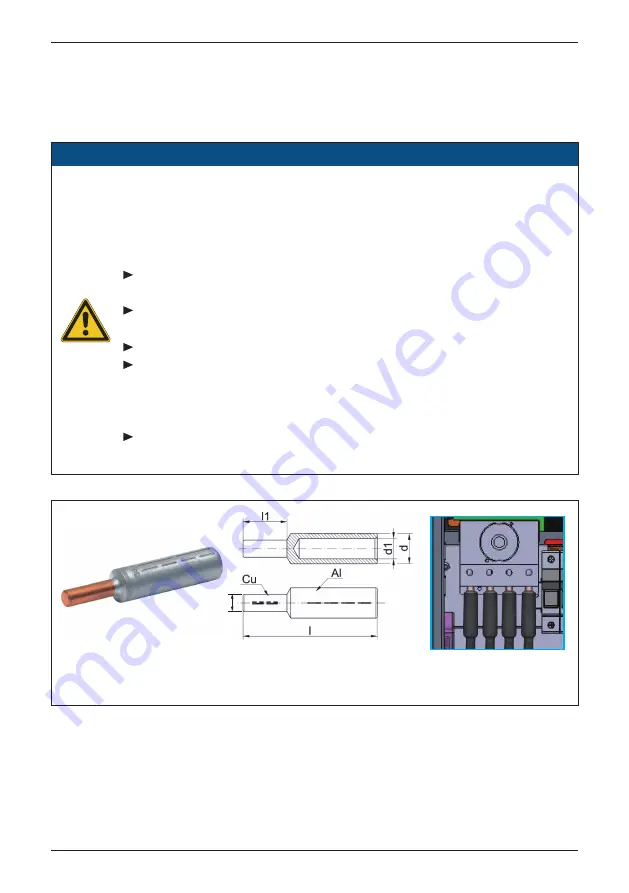

Figure 3-18 : Guideline for bi-metal adapter

Type: Compression joints

with Cu bolts, Al

For M80/60U, d

≦

18mm, e

≦

10mm

Heat-Shrinkable tube must be applied on Al part

e

41

Installation

Summary of Contents for M60U

Page 2: ......

Page 89: ...Figure 5 6 Remove screws as indicated unplug connectors DC SPDs AC SPDs 89 Maintenance...

Page 128: ......

Page 129: ......