C1000 Series Service & Maintenance Manual

Service and Repair

SECTION IV

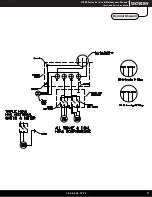

Fig. L

Fig. M

Fig.K

After removing the wiring from the compressor motor, the motor may be removed by unscrewing the air discharge hose on the front left

cylinder, and removing the four ½” nuts securing the head to the vibration isolation mounts.

2. Power Switches: The toggle switches located on the front center of the

compressor control the individual compressor motors. If the pressure

switch is operating correctly, remove the motor terminal cover on the back

of the desired compressor motor. With the power switch in the on “up”

position, check for voltage to the compressor motor as shown in Fig. K. If

the proper voltage is present, the power switch is good. If no voltage is

present at the motor, replace the corresponding power switch.

3. Compressor Motor (head): The compressor motor turns the compressor crankshaft to generate air

fl

ow to the system. If the correct

voltage is present on the L1 and L2 terminals as described in the testing procedure listed above, but the compressor hums and does not

start, the start capacitor is defective. If the correct voltage is present but nothing happens, the head is defective.

To replace the motor, it is not required to cut the spade terminals from the wiring (see Figures L and M) for proper disassembly without

cutting factory wiring.

1.800.624.2793

13

Unpacking

Electrical