Compressor Overheats

Moisture In Air Lines

C1000 Series Service & Maintenance Manual

Service and Repair

SECTION IV

Moisture In Air Lines

Clogged Air Intake Filter

Exhaust Valve

Too Much Run Time

Ambient Temperature Too High

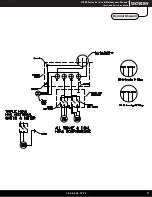

Time Operated Purge Valve

Timers Incorrectly Set

Strainer Valve Off or Clogged

Coalescing Filter Auto-Drain

Desiccant Failure

Compressor Undersized

Faulty Dental Unit Diaphragm

Clean or replace intake

fi

lter element.

Clean & Replace valve-plate.

Air leaks; compressor too small to meet demand.

Add ventilation and \ or cooling to equipment room.

Clean or replace solenoid valve assembly.

Left Timer knob “duration of purge” set at 10 seconds.

Right Timer knob “purge interval” set at 7 minutes.

Clean strainer and ensure valve is on.

Clean or replace as needed.

Replace drying chamber assembly.

Additional or larger compressor to met demand requirements.

Check Master shut-off and water relay diaphragms.

Unpacking

Troubleshooting Chart

TROUBLESHOOTING CHART

SYMPTOMS CAUSES POSSIBLE REMEDY

1.800.624.2793

11