C1000 Series Service & Maintenance Manual

Theory of Operation

Theory of Operation

THEORY OF OPERATION

While Running

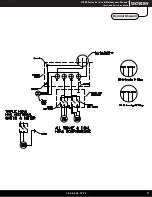

To start the compressor, the user shall activate the compressor head or heads with the power switches located on the front center

of the machine. The selected motors will then begin to run and build pressure in the tank and piping system.

A. The air is taken in through the intake

fi

lters, located on the rear of each compressor cylinder. The dirt and dust is

fi

ltered out

of the intake

fi

lter to 5 microns in this process.

B. The air is then compressed with the pistons in each cylinder, and then travels through the after-cooler (copper) tubing, which

cools the air to help condense any moisture “humidity” taken in during the process of compression.

C. The wet / dirty compressed air and condensed moisture then travel through a coalescing

fi

lter assembly. This

fi

lter allows the

condensed moisture to fall to the bottom of the

fi

lter bowl via gravity, where it will be automatically expelled via the

fl

oat

drain contained in the bottom of the

fi

lter bowl. The compressed air also travels through the coalescing

fi

lter element, which

removes 99.998% of all particles down to 0.01 microns. A

fi

lter change indicator located on the top of the

fi

lter housing

shows the condition of the element, and alerts the operator as to when the element is in need of replacement. GREEN

indicates the element has more useful life, while RED indicates the element is in need of replacement.

NOTE:

The indicator only functions while compressed air is traveling through the

fi

lter with compressor running. The indicator

will ALWAYS read “GREEN” with compressors not running.

D. The compressed air then travels through the bottom of the desiccant “drying chamber”, where the remaining contained

moisture is reduced to a pressure dewpoint of -100

°

F, and then travels into the main storage tank for use in the dental

operatory.

E. When reaching its cut-off pressure of 100psi, the pressure switch will open and the compressor motors will stop.

NOTE

: The time operated dryer purge valve DOES NOT open and purge when compressor stops, as it does on most competitive

brands. See Theory of Operation “While Not Running” for more information as to the proper operation of our purge valve.

SECTION II

1.800.624.2793

5