1 www.dcionline.com

C1000 Series Service & Maintenance Manual

Theory of Oporation

Theory of Operation

THEORY OF OPERATION

While Not Running

A. When the motors stop after reaching the cut-out pressure of 100psi, the user will have clean / dry air ready for use in

the dental operatory. The compressor will remain in this “idle” state until the tank pressure drops to 80 psi, at which time

the compressor motors will turn on and return the running mode of operation.

B. The “Time Operated” dryer purge valve operates on a time basis instead of a “single cycle” basis used on most other

types of dental air compressors. Two timers, “located on the front of the valve assembly”, control how often and the

duration of each purge cycle.

SECTION II

NOTE

: The compressor does not purge when the

compressor cycles off!

C. The “Left” timer knob on the purge valve, controls the

duration of the purge cycles. This timer is factory preset

and should not be adjusted. The factory setting is at the

maximum of 10 seconds.

D. The “Right” timer knob on the purge valve controls how

often the compressor purges moisture from the drying

chamber. The factory setting is 7 minutes, and should NOT

be adjusted.

E. A “TEST” button is located between the two timer knobs

to allow a technician to verify that the valve is operating

correctly.

By purging the drying chamber on a time basis, the DCI air

compressors ensure the drying chamber desiccant remains dry,

even during heavy usages, for consistent air quality.

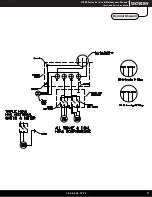

Plumbing Schematic

Left

Motor

Right

Motor

Check

Valve

Check

Valve

Aftercooling

Tubing

Coalescing

Filter

Condensate

Drain

Drying Chamber

Flow/Check

Drying System

Pressure Gauge

Dryer Bypass

Ball Valve

To

Storage

Tank

Strainer

Shutoff

Valve

Time Purge

Valve

w w w.dcionline.com

6