step 5.

Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

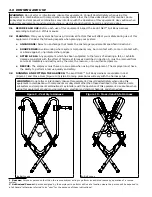

3.12 Fire and resCue Class ii harness donning For resCue: The ExoFit NEX™ Fire and Rescue

Harness includes leg straps that permit the harness to be used for rescue work. To configure the harness for

rescue, follow Figure 5, Steps 1 through 5, to fit the leg straps to the user. Follow the steps in Figure 6 to

convert the harness to Class III.

Figure 5 - Fire and rescue harness Belt donning For rescue

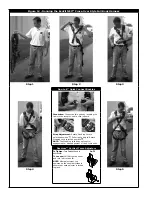

rescue, step 1

rescue, step 2

rescue, step 3

rescue, step 4

rescue, step 5

proceed to Figure 6, steps 1 - 6

Figure 5

step 1.

Suspend the harness by holding each end. D-Rings and the carabiner should be facing forward.

Ensure all straps are not twisted.

step 2.

Grasp the quick connect buckle at the end of the web belt and bring it around your waist so that

the buckle is just behind your left hip. Lock the tab located at the opposite end of the web belt

into the quick connect buckle. You will hear a click when the tab engages properly.

step 3.

Reach between your legs and grasp the leg strap on your left side. Bring the strap up around the

back of your left leg. Insert the tab on the strap handing from the left side of the belt into the

quick connect buckle of the strap. You will hear a click when the tab engages properly.

step 4.

Reach between your legs and grasp the leg strap on your right side. Bring the strap up around

the back of your right leg. Insert the tab on the strap handing from the right side of the belt into

the quick connect buckle of the strap. You will hear a click when the tab engages properly.

To adjust the leg straps, unlock the webbing lock on the quick connect buckle and pull on the

strap. A plastic end keeper on the end of the strap will stop it from pulling completely out of

the buckle. When the strap is properly adjusted, lock the webbing lock. To release the buckle,

press the silver-colored tabs on the buckle towards each other with one hand, while pulling on the

tab portion of the buckle with the other hand.

step 5.

Grasp the waist-level strap ends on right and left sides of the harness. Pull both ends forward

until all slack is removed from the waist strap and the strap is comfortably tight around your

waist. Insert strap ends into the waist strap keeper loops on the right and left sides of the

harness.

waRning: The Fire and Rescue Harness meets the requirements of NFPA 1983, Standard on Life

Safety Rope and Equipment for Emergency Services, 2012 Editions, and the Optional Flame Resistance

Requirements of NFPA 1983, Class II. When used in conjunction with DBI/SALA part numbers 1114000,

1114000H, 1114001, 1114001H 1114002, or 1114002H, the Fire and Rescue Harness meets the

requirements of Class III but IS NOT FLAME RESISTANT. See Harness labels 5909121 and 5909122.