2.9 MAKING

CONNECTIONS:

Use only self-locking snap hooks and carabiners with this equipment. Only use

connectors that are suitable to each application. Ensure all connections are compatible in size, shape and

strength. Do not use equipment that is not compatible. Ensure all connectors are fully closed and locked.

DBI-SALA connectors (snap hooks and carabiners) are designed to be used only as speci

fi

ed in each

product’s user’s instructions. See Figure 7 for illustration of the inappropriate connections stated below. DBI-

SALA snap hooks and carabiners should not be connected:

A. To a D-ring to which another connector is attached.

B. In a manner that would result in a load on the gate.

C. In a false engagement, where features that protrude from the snap hook or carabiner catch on the

anchor and without visual con

fi

rmation seems to be fully engaged to the anchor point.

D. To each other.

E. Directly to webbing or rope lanyard or tie-back (unless the manufacturer’s instructions for both the

lanyard and connector speci

fi

cally allow such a connection).

F. To any object which is shaped or dimensioned such that the snap hook or carabiner will not close and

lock, or that roll-out could occur.

G.

In a manner that does not allow the connector to align with the fall arrest device (i.e., lanyard) while

under load.

NOTE:

Other than 3,600 lb. (16 kN) gated hooks, large throat opening snap hooks should not be

connected to standard size D-rings or similar objects which will result in a load on the gate if the hook or

D-ring twists or rotates. Large throat snap hooks are designed for use on

fi

xed structural elements such as

rebar or cross members that are not shaped in a way that can capture the gate of the hook.

Other Restrictions:

•

Do not make connections where the hook locking mechanism can come into contact with a structural

member or other equipment and potentially release the hook.

•

Do not connect a snap hook into a loop or thimble of a wire rope or attach in any way to a slack wire

rope.

•

The snap hook must be free to align with the applied load as intended (regardless of the size or shape of

the mating connector).

•

A carabiner may be used to connect to a single or pair of soft loops on a body support such as a body

belt or full body harness, provided the carabiner can fully close and lock. This type of connection is not

allowed for snap hooks.

•

A carabiner may be connected to a loop or ring connector that is already occupied by a choker style

connector. This type of connection is not allowed for snap hooks.

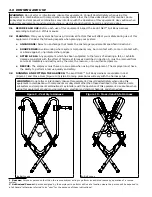

Figure 6 - Unintentional Disengagement (Rollout)

If the connecting element to which a snap hook (shown) or carabiner

attaches is undersized or irregular in shape, a situation could occur

where the connecting element applies a force to the gate of the snap

hook or carabiner. This force may cause the gate (of either a self-

locking or a non-locking snap hook) to open, allowing the snap hook

or carabiner to disengage from the connecting point.

Small ring or other

non-compatibly

shaped element

1.

Force is applied

to the Snap

Hook.

2.

The

Gate

presses against

the Connecting

Ring.

3.

The Gate opens

allowing the

Snap Hook to

slip off.

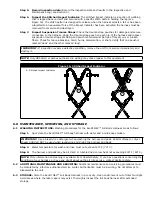

Figure 7 - Inappropriate Connections