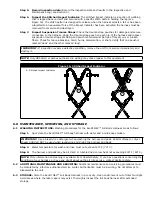

2.10 CONNECTING SUBSYSTEMS:

Connecting subsystems (self-retracting lifeline, lanyard, rope grab and

lifeline, cable sleeve) must be suitable for your application (see Table 1). See subsystem manufacturer’s

instructions for more information. Some harness models have web loop connection points. Do not use snap

hooks to connect to web loops. Use a self-locking carabiner to connect to a web loop. Ensure the carabiner

cannot cross-gate load (load against the gate rather than along the backbone of the carabiner). Some

lanyards are designed to choke onto a web loop to provide a compatible connection. See Figure 8. Lanyards

may be sewn directly to the web loop forming a permanent connection. Do not make multiple connections

onto one web loop, unless choking two lanyards onto a properly sized web loop.

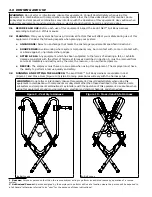

Figure 8 - Web Loop Connection

1.

Insert Lanyard Web Loop (A) through Web Loop

or D-ring on harness (B).

2.

Insert opposite end of Lanyard through the

Lanyard Web Loop.

3.

Pull the Lanyard through the connecting Web

Loop to secure.

B

A

1

2

3

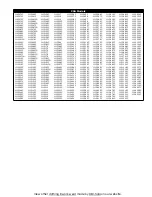

2.11 ANCHORAGE & ANCHORAGE STRENGTH:

Anchorage and anchorage strength requirements are dependent

on the full body harness application (see Figure 3). In accordance with ANSI Z359.1, anchorages selected for Fall

Arrest Systems must meet the anchorage strength requirements de

fi

ned in Table 2.

Table 2 - Anchorage Strength Requirements

Fall Arrest

1

Non-Certi

fi

ed Anchorages:

5,000 lbs (22.2 kN)

Certi

fi

ed Anchorages

2

:

2 times the Maximum Arresting Force for Certi

fi

ed

Anchorages

Restraint

1

Non-Certi

fi

ed Anchorages

1,000 (4,5 kN)

Certi

fi

ed Anchorages

2

:

2 times the foreseeable force for certi

fi

ed anchorages.

Work Positioning

1

Non-Certi

fi

ed Anchorages

3,000 lbs (13.3 kN)

Certi

fi

ed Anchorages

2

:

2 times the foreseeable force for certi

fi

ed anchorages.

Rescue

1

Non-Certi

fi

ed Anchorages

3,000 lbs (13.3 kN)

Certi

fi

ed Anchorages

2

:

5 times the foreseeable force for certi

fi

ed anchorages.

Climbing

The structure to which a climbing system is attached must sustain the loads required by that

particular system. See the instructions for the climbing system for requirements.

1 Multiple Systems:

When more than one of the de

fi

ned system is attached to an anchorage, the strength de

fi

ned for Non-Certi

fi

ed

or Certi

fi

ed anchorages shall be multiplied by the number of systems attached to the anchorage.

2 Certi

fi

ed Anchorage:

An anchorage for fall arrest, positioning, restraint, or rescue systems that a quali

fi

ed person certi

fi

es to be

capable of supporting the potential fall forces that could be encountered during a fall or that meet the criteria for a certi

fi

ed anchor-

age prescribed in this standard.