DFX-7

Ultrasonic Flaw Detector

149

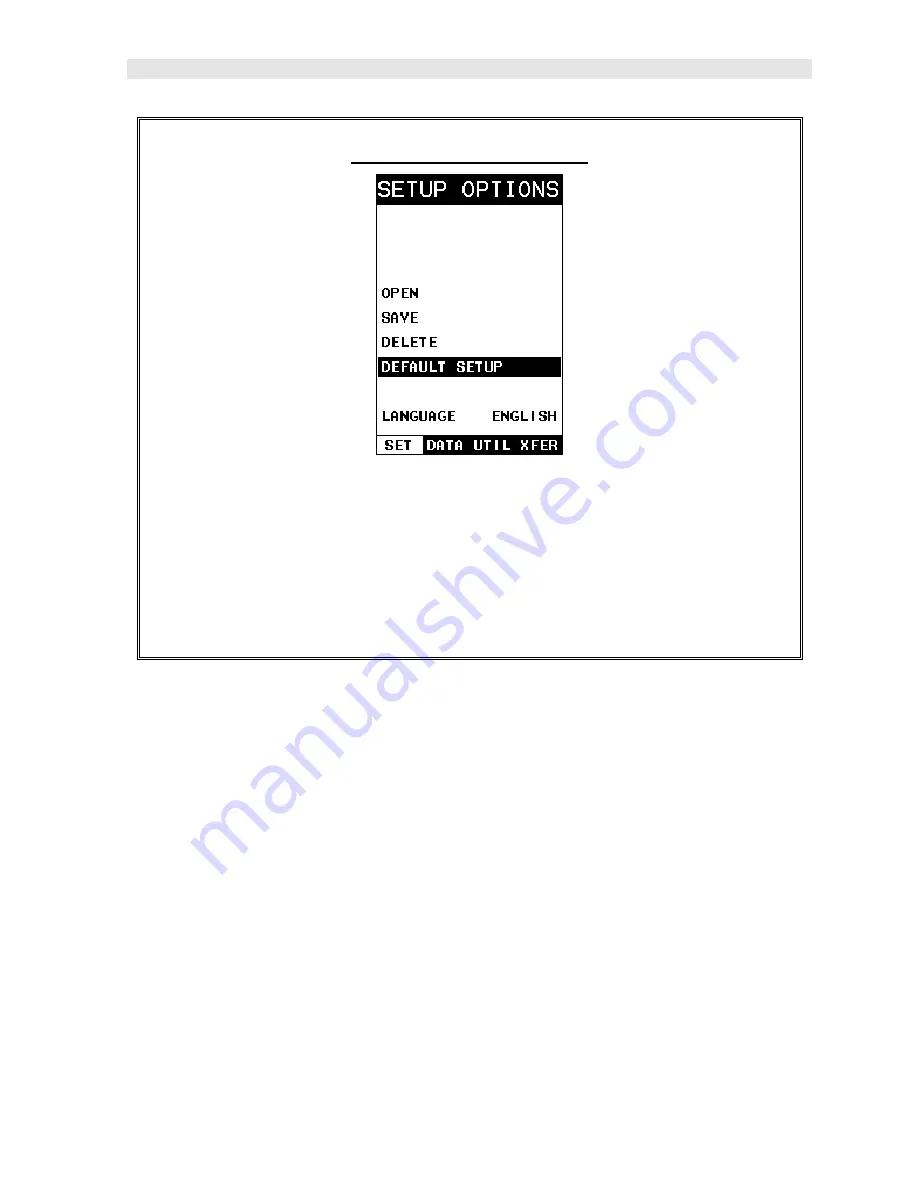

Using the Default Setup

1) Press the

MENU

key once to activate the menu items tab. Press the

MENU

key multiple times to tab right and the

ESC

key multiple times to tab left until

the

SETUP

menu is highlighted and displaying the submenu items.

2) Use the

UP

and

DOWN

arrow keys to scroll through the sub menu items

until

DEFAULT SETUP

is highlighted.