[10]

MAN #650500G

Quick tips:

While the BIM is operating, the dot in the upper left corner of the display will indicate the status:

•

On steady indicates it is powered up but not receiving any BIM bus activity.

•

Flashing indicates it is communicating on the BIM bus.

•

A dot in the upper center indicates that there is an engine code set (MIL active).

•

If the display

is sequencing through “

”, “

”, “

”, then it is scanning to try and communicate with the vehicle

bus but cannot get an answer.

o

This could indicate that the ODBII connector is not wired properly

o

The BIM-01-2 is not compatible with following the ECU types

▪

European or Asian protocols

▪

Non SAE standard (US) CAN bus

▪

Pre OBDII years

▪

Chrysler ECUs older than 2004

To see the sensor and channel status on the BIM display, press and hold the switch to cycle through the screens.

The first items to show is the protocol letter with a n

umber “

” (Ford), “

” (GM/Chrysler J-1850), or “

” (CAN).

If the first thing displayed is “

”, the BIM-01-2 is reading CAN, and three extra readings.

Speed, RPMs, and engine temp are expected, everything else is an extra.

The next screens will indicate which data is available:

“

” - Engine Oil Pressure

“

” - Transmission Fluid Temp

“

” - Ambient Air Temp

“

” - Intake Air Temp

“

” - Gear Position

“

” - Fuel Level Input

“

” - Boost/Vacuum data

“

” - Speed data

“

” - RPM/Tachometer data

“

” - Engine Coolant Temp

If you do not see any number of these listed it means it may not be transmitted for the BIM-01-2 to read.

Emissions note:

If your vehicle requires emissions testing in your area, the check engine feature of this unit cannot be used to operate the

Check Engine or Service Engine indicator.

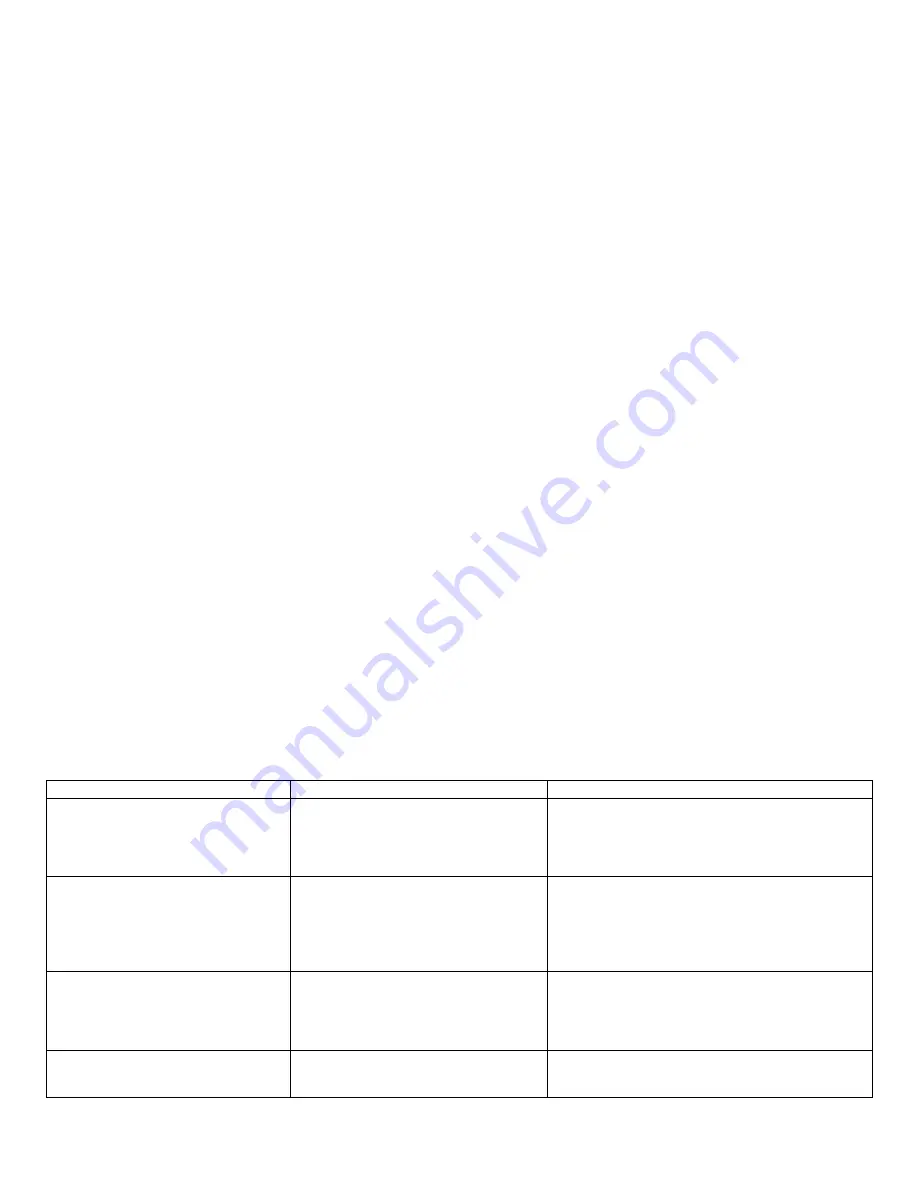

Troubleshooting guide:

Problem

Possible cause

Solution

No BIM data on instrument readout;

BIM does not light up.

PWR wire does not have power.

GND wire is not properly grounded.

Power/data harness is damaged.

Module is damaged.

Connect to a location that has +12V key-on power.

Connect to a different ground location.

Inspect harness. Repair or replace any damaged

areas.

Return for service. (see instructions)

No BIM data on instrument readout;

BIM

display is scanning “J”, “F”, “C”

OBD-II Interface cable is not connected.

The vehicle bus is not compatible.

The bus ID is not compatible.

Connect the supplied OBD-II cable between the

BIM unit and the vehicle diagnostic plug.

Vehicles using the ISO 9141-2 protocol are not

compatible with the BIM-01-2.

Some vehicles require the bus ID to be changed to

, or

.

No BIM data on instrument readout;

BIM has a steady dot lit.

Interface cable is not connected.

Interface cable is loose.

On VHX systems, the BIM display for

this channel is disabled.

Connect the supplied harness between the BIM

unit and the instrument system control box.

Ensure both ends of the cable are seated securely.

Follow instructions in VHX manual to enable the

BIM display screen.

BIM

display shows “

:

”

Data cable is damaged or connected

improperly.

Another module on the bus is damaged.

Inspect and replace harness or power/data

harness.

Inspect other modules on the data bus.

Summary of Contents for BIM-01-2

Page 11: ... 11 MAN 650500G Notes ...