The following table describes the torques for tightening nuts of different pipe diameters.

Pipe Diameter

Tightening Torque

1/4” (inch)

15-30 (N·m)

3/8” (inch)

35-40 (N·m)

5/8” (inch)

60-65 (N·m)

1/2” (inch)

45-50 (N·m)

3/4” (inch)

70-75 (N·m)

7/8” (inch)

80-85 (N·m)

3. The bending angle of the refrigerant pipe shall not be too small, otherwise the pipe may break. Please use

a bender when bending the

pipes.

4. Use sponge to wrap the refirgerant pipe and joint without thermal insulation, and use plastic tape to

bundle the sponge.

5. Remove the caps of the liquid valve and the gas valve.

6. Use an inner hexagon spanner to loose off the spool of the liquid valve for 1/4 circle. At the same time,

7. Refrigerant gas shall come out in 15 seconds. Then, close the one way valve

immediately and tighten the bonnet.

8. Fully open the spools of the liquid valve and the gas valve (refer to Fig. 8.12).

9. Tighten the caps of valves. Then use soap water or leakage detector to check if there is leakage at the

position where the indoor unit or the outdoor unit is connected with the refrigerant pipes.

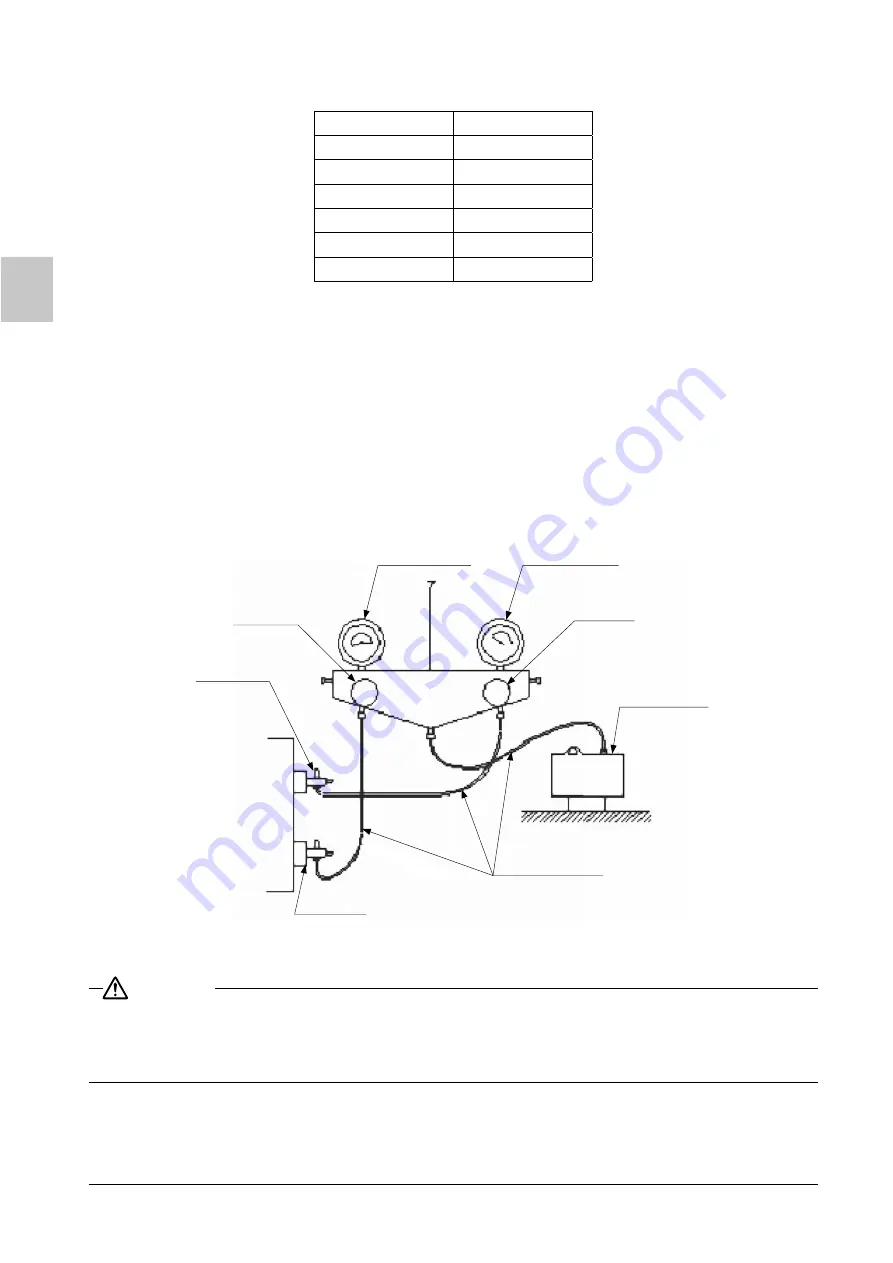

10. If possible, use a vacuum pump to remove air out the valve. Refer to Fig. 8.13.

Pressure Gage

“LO” Knob

Pressure Gage

“HI” Knob

Vacuum Pump

Liquid Valve

Gas Valve

Connecting Hose

Fig.8.13

CAUTION

1. When connecting the indoor unit with the refrigerant pipe, do not pull the big and small joints of the indoor

unit forcefully, so as to prevent the capillary of the indoor unit and other pipes from breaking and leaking.

2. The

pipe shall be supported by proper bracket.

of

The weight of the pipe shall not be withstand

by the unit.

English

32

use a screwdriver to lift the spool. Then there is discharge of gas.

n

refrigerant

refrigerant