9

English

•

Make sure wiring the units, ground wiring and remote controller wiring are not caught inside the indoor

unit.

■

When screwing in the indoor unit

•

Remove the front grill.

(Refer to Fig. 7)

•

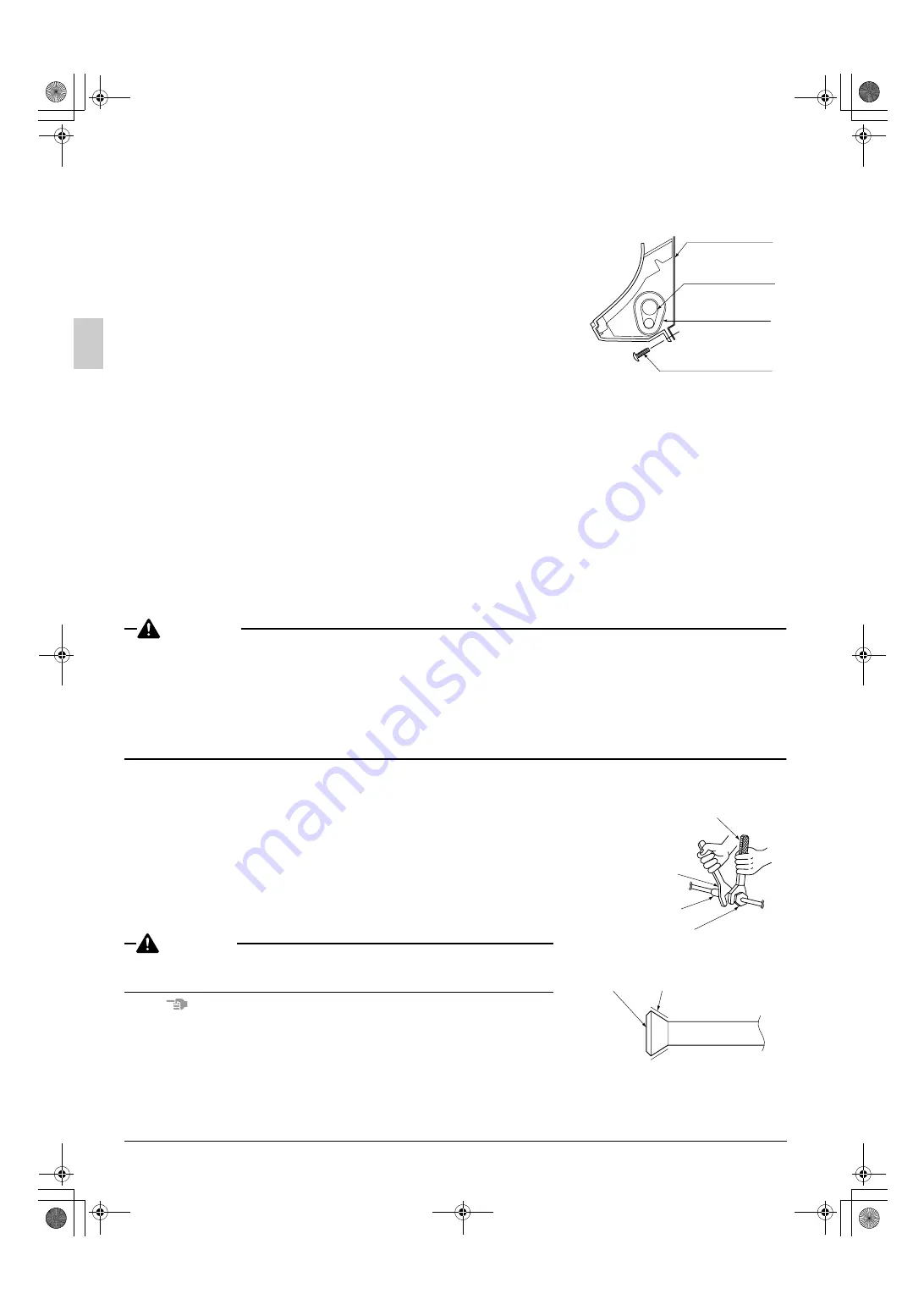

Secure the indoor unit to the installation panel (1) with the securing

screws (6).

(Refer to Fig. 11)

5. REFRIGERANT PIPING WORK

〈〈〈〈

For refrigerant piping of outdoor units, see the installation manual attached to the outdoor unit.

〉 〉 〉 〉

〈〈〈〈

Execute heat insulation work completely on both sides of the gas piping and the liquid piping.

Otherwise, a water leakage can result sometimes.

〉 〉 〉 〉

(When using a heat pump, the temperature of the gas piping can reach up to approximately 120°C, so use

insulation which is sufficiently resistant.)

〈〈〈〈

Also, in cases where the temperature and humidity of the refrigerant piping sections might exceed

30°C or RH80 %, reinforce the refrigerant insulation. (20 mm or thicker) Condensation may form on the

surface of the insulating material.

〉〉〉〉

〈〈〈〈

Before refrigerant piping work, check which type of refrigerant is used. Proper operation is not pos-

sible if the types of refrigerant are not the same.

〉〉〉〉

CAUTION

• Use a pipe cutter and flare suitable for the type of refrigerant.

• Apply ester oil or ether oil around the flare section before connecting.

• To prevent dust, moisuture or other foreign matter from infiltrating the tube, either pinch the end

or cover it with tape.

• Do not allow anything other than the designated refrigerant to get mixed into the refrigerant

circuit, such as air, etc. If any refrigerant gas leaks while working on the unit, ventilate the room

thoroughly right away.

•

The outdoor unit is charged with refrigerant.

•

Use copper alloy seamless pipes (ISO 1337)

•

Be sure to use both a spanner and torque wrench together, as shown

in the drawing, when connecting or disconnecting pipes to/from the

unit.

(Refer to Fig. 12)

•

Refer to “Table 2” for the dimensions of flare nut spaces.

•

When connecting the flare nut, coat the flare section (both inside and

outside) with ester oil or ether oil, rotate three or four times first, then

screw in.

(Refer to Fig. 13)

CAUTION

Over-tightening may cause the flare nuts to crack or the refrigerant to

leak.

NOTE

•

Use the flare nut included with the unit main body.

Installation panel

(accessory) (1)

Refrigerant piping

Insulating tape

(accessory) (4)

M4 × 12L

(accessory) (6)

Fig. 11

Torque wrench

Spanner

Piping union

Flare nut

Fig. 12

Ester oil or ether oil

Fig. 13

01_EN_3P083811-3T.fm Page 9 Friday, September 3, 2004 10:17 AM