DEIMHP0140521_00EN

26

EWYT~CZ / EWAT~CZ

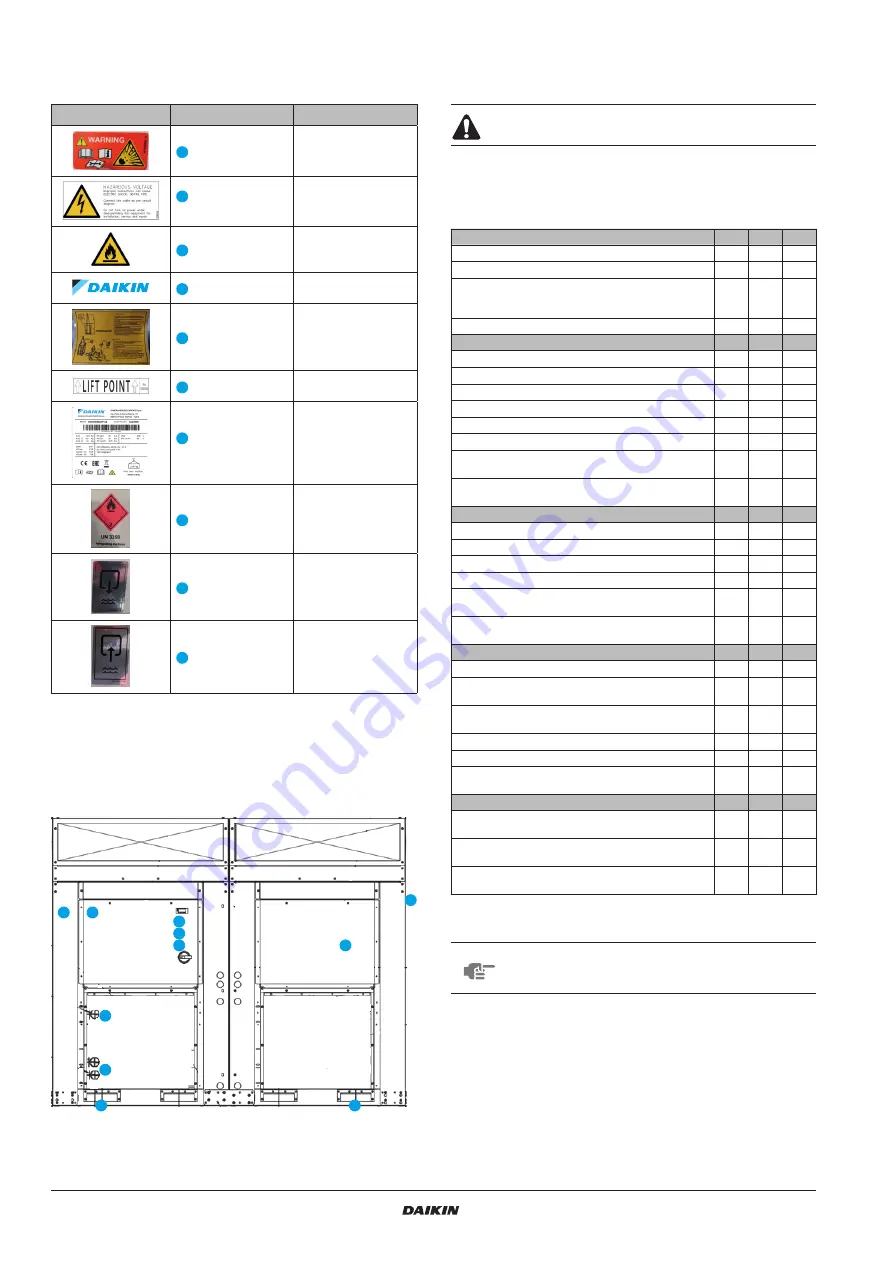

8. List of tHe LabeLs aPPLieD to tHe

unit

Labels

Description

Location

Generical warning

On the electric panel

(outside)

Hazardous voltage

warning

On the electric panel

(outside)

A2L symbol

On the electric panel

(outside)

Manufacturer’s logo

On the electric panel

(outside)

Lifting instruction*

One on the unit frame

and one on the

packaging

Lift point label

One on the unit panel

near the unit lifting holes

Unit ID plate

information

On the unit frame

(outside)

UN 3358 labels*

On the packaging

Water outlet

On the unit panel near

the outlet connection

Water inlet

On the unit panel near

the inlet connection

* Labels on the unit packaging

Table 12 –

Labels applied to the Unit

With the exception of the unit’s identification plate, which is always in

the same position, the other plates may be located in different

positions depending on the model and the options present on the unit.

Figure 21 –

Labels on the unit

9. CHeCKs for tHe first startuP

The unit must be started for the first time ONLY by

authorized DAIKIN personnel.

The unit must absolutely not be put into operation, even if for a very

short period, without having first meticulously checking the following

list in its entirety.

General

Yes

No

N/A

Check for external damage

Open all isolation and / or shutoff valves

Verify that the unit is pressurized with refrigerant in all

of its parts before making the connection to the

hydraulic circuit.

Check the oil level in the compressors

Chilled Water

Yes

No

N/A

Piping complete

Water System filled and vented

Pumps installed & operational (rotation checked)

Strainers installed and clean

Controls (3way valves, bypass valves, etc.) operable

Flow switch installed.

Water system operated and flow balanced to meet

unit design requirements

Proper glycol percentage for the application in

accordance with Daikin specifications

Condenser Water

Yes

No

N/A

Cooling tower flushed, filled and piping vented

Pumps installed & operational (rotation checked)

Strainers installed and clean

Controls (3way valves, bypass valves, etc.) operable

Water system operated and flow balanced to meet

unit design requirements

Proper glycol percentage for the application in

accordance with Daikin specifications

Electrical

Yes

No

N/A

Power leads connected to unit main terminal block

Power leads have been checked for proper electrical

phasing UVW for L1, L2, & L3 respectively.

All interlock wiring complete and complies with Daikin

specifications

Pump starter and interlocks wired

Cooling tower fans and controls wired

Wiring complies with National Electrical Code and

local codes

Miscellaneous

Yes

No

N/A

Unit installed in accordance with Daikin IOM

specifications (leveling, space requirements, …)

Thermometer wells, thermometers, gauges, control

wells, controls, etc., installed

A minimum system load of 60% of machine capacity

is available for testing and adjusting controls

Table 13 –

Checks before starting up the unit

NOTE

This list must be completed and sent to the local Daikin

Service department at least two weeks before the

startup date.

Summary of Contents for EWAT016CZN-A1

Page 2: ......

Page 28: ...Notes...