D-EIMAC00907-16EN - 13/20

Electrical Installation

General specifications

All electrical connections to the unit must be carried out

in compliance with laws and regulations in force.

All installation, management and maintenance activities

must be carried out by qualified personnel.

Refer to the specific wiring diagram for the unit you have

bougth. Should the wiring diagram not be on the unit or

should it have been lost, please contact your

manufacturer representative, who will send you a copy.

In case of discrepance between wiring diagram and

electrical panel/cables, please contact the manufacturer

representative.

Only use copper conductors. Failure to use copper conductors

could result in overheating or corrosion at connection points

and could damage the unit.

To avoid interference, all control wires must be connected

separately from the power cables. Use different electrical

passage ducts for this purpose.

Particular care must be taken when realizing wire connections

to the switchbox; if not properly sealed, cable entries may

allow ingress of water into the switchbox which may cause

damage to the equipment inside.

Before any installation and connection works, the unit

must be switched off and secured. Since this unit

includes inverters, the intermediate circuit of the

capacitors remains charged with high voltage for a short

period of time after being switched off. Do not operate to

the unit before 5 minutes after the unit has been

switched off.

This unit includes non-linear loads such as inverters, which

have a natural current leakage to earth. If an Earth Leakage

Detector is installed upstream the unit, a type B device with a

minimum threshold of 300 mA must be used.

This product complies with EMC standards for industrial

environments. Therefore it is not intended for use in residential

areas, e.g. installations where the product is connected to a

low voltage public distribution system. Should this product

need to be connected to a low voltage public distribution

system, specific additional measures will have to be taken to

avoid interference with other sensitive equipment.

Operation

Operator’s responsibilities

It is essential that the operator is appropriately trained and

becomes familiar with the system before operating the unit. In

addition to reading this manual, the operator must study the

microprocessor operating manual and the wiring diagram in

order to understand start-up sequence, operation, shutdown

sequence and operation of all the safety devices.

During the unit

’s initial start-up phase, a technician authorized

by the manufacturer is available to answer any questions and

to give instructions as to the correct operating procedures.

The operator must keep a record of operating data for every

installed unit. Another record should also be kept of all the

periodical maintenance and servicing activities.

If the operator notes abnormal or unusual operating conditions,

he is advised to consult the technical service authorized by the

manufacturer.

Maintenance

Routine maintenance

This chiller must be maintained by qualified technicians.

Before beginning any work on the system the personnel

shall assure that all security precautions have been taken.

Neglecting unit maintenance in these environments, could

degrade all parts of the units (coils, compressors, frames,

pipes, etc..) with negative effect on performances and

functionality.

There are two different levels of maintenance, which can be

chosen according to the type of application (critical/non critical)

or to the installation environment (highly aggressive).

Examples of critical applications are process cooling, data

centres, etc.

Highly Aggressive Environments can be defined as the follows:

Industrial environment (with possible concentration

of fumes result of combustion and chemical process)

Costal environment;

Highly polluted urban environment;

Rural environment close to of animal excrement and

fertilizers, and high concentration of exhaust gas

from diesel generators.

Desert areas with risk of sandstorms;

Combinations of the above

Table 2 lists all Maintenance activities for standard applications

and standard environment.

Table 3 lists all Maintenance activities for critical applications

or highly aggressive environment.

Following below instructions is mandatory for cases listed

above, but also advised for units installed in standard

environments.

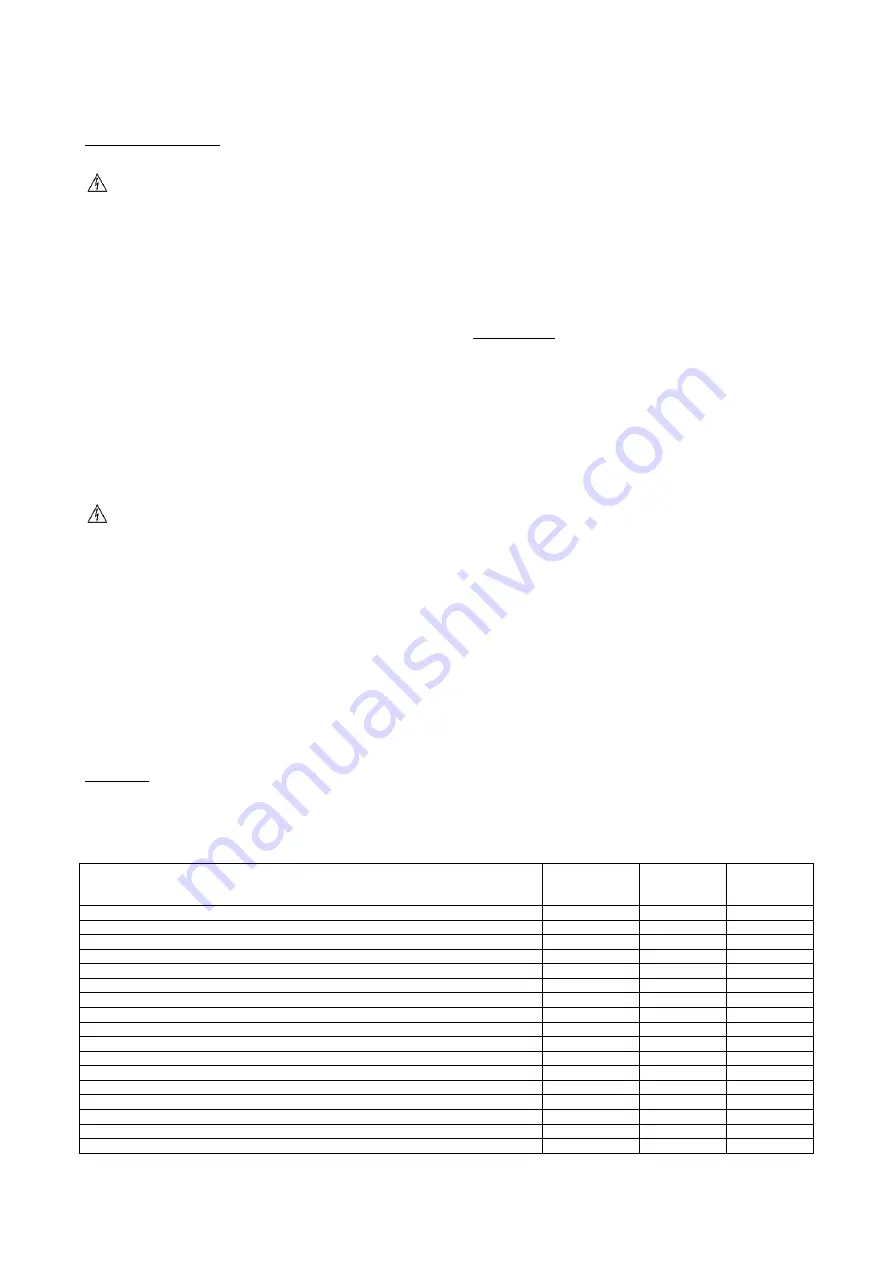

Table 2

– Standard Routine Maintenance Plan

List of Activities

Weekly

Monthly

(Note 1)

Yearly/Seas

Onal

(Note 2)

General:

Reading of operating data (Note 3)

X

Visual inspection of unit for any damage and/or loosening

X

Verification of thermal insulation integrity

X

Clean and paint where necessary

X

Analysis of water (6)

X

Check of flow switch operation

X

Electrical:

Verification of control sequence

X

Verify contactor wear

– Replace if necessary

X

Verify that all electrical terminals are tight

– Tighten if necessary

X

Clean inside the electrical control board

X

Visual inspection of components for any signs of overheating

X

Verify operation of compressor and oil heater

X

Measure compressor motor insulation using the Megger

X

Clean air intake filters of the electrical panel

X

Summary of Contents for EWAD TZ

Page 17: ...D EIMAC00907 16EN 17 20...

Page 18: ...D EIMAC00907 16EN 18 20...

Page 19: ...D EIMAC00907 16EN 19 20...