17

NOTE:

Except during brief periods when gas pressures are

being measured by qualified service personnel, the furnace

access panel must always be secured in place when the fur-

nace is in operation. An inspection port in the access panel

is provided to monitor the flame.

The first step in checking out the gas-fired furnace is to test

the gas supply piping to the unit for tightness and purge the

system of air using methods outlined in the latest edition of

the National Fuel Gas Code ANSI Z223.1. Verify that the

disconnect switch is in the “OFF” position. A soapy water

solution should be used to check for gas leaks. Since the

unit is subject to considerable jarring during shipment, it is

extremely important that all gas connections and joints be

tested for tightness. Gas piping downstream from the unit

inlet should be checked for leaks during the subsequent se-

quence check.

The supply gas pressure should be adjusted to 7.0” w.c. on

natural gas and 11.0” on LP gas with the gas burners oper-

ating. If there is more than one unit on a common gas line,

the pressures should be checked with all units under full fire.

A supply pressure tap is provided on the upstream side of

the gas valve. A manifold pressure tap is provided on the

gas valve. The normal manifold pressure for full input is 3.5”

w.c. on natural gas and 9.5” w.c. for propane gas. Low fire

natural gas 2.0” w.c., 6.0” low fire propane gas. Minimum

gas supply pressure is 5.5” w.c. for natural gas and 11.0” for

propane gas. In order to obtain rating, gas supply pressure

must be 11.0” w.c. for propane gas.

The pressure regulator on LP gas models is adjusted for 9.5”

w.c. manifold pressure and is intended to prevent over-fir

-

ing only. Do not attempt adjustment of the built-in pressure

regulator unless the supply pressure is at least 7.0” w.c. on

natural gas or 13.0” w.c. on propane gas. Check the location

of the ignition electrode and the flame sensor for correct

gap setting.

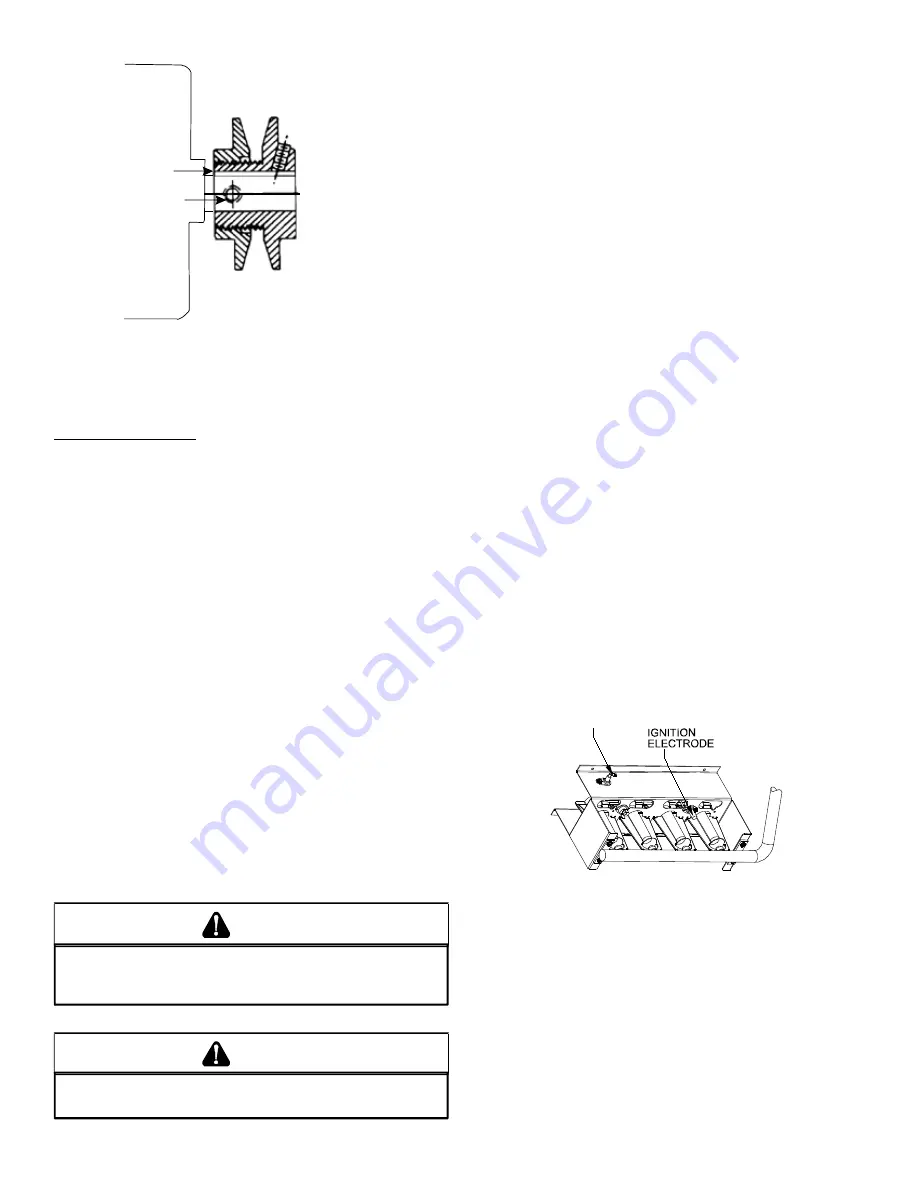

FLAME

SENSOR

Flame Sensor and Ignition Electrode Location

C

B

VL & VM

NOTE:

Do NOT operate sheave with flange projecting be

-

yond the hub end.

GAS SYSTEM CHECK

Pre-Operation Checks

1. Close the manual gas valve external to the unit.

2. Turn off the electrical power supply to the unit.

3. Set the room thermostat to its lowest possible setting.

4. Remove the heat exchanger door on the side of the unit

by removing screws.

5. This unit is equipped with an ignition device which auto-

matically lights the main burner. DO NOT try to light burn-

er by any other method.

6. Move the gas control valve switch to the OFF position. Do

not force.

7. Wait five minutes to clear out any gas.

8. Smell for gas, including near the ground. This is important

because some types of gas are heavier than air. If you

have waited five minutes and you do smell gas, imme

-

diately follow the warnings on page 3 of this manual. If

having waited for five minutes and no gas smell is noted,

move the gas control valve switch to the ON position.

9. Replace the heat exchanger door on the side of the unit.

10. Open the manual gas valve external to the unit.

11. Turn on the electrical power supply to the unit.

12. Set the thermostat to desired setting.

g

as

s

uPPly

P

ressures

& r

egulatOr

a

djustments

S

HOULD

OVERHEATING

OCCUR

OR

THE

GAS

SUPPLY

FAIL

TO

SHUT

OFF

,

TURN

OFF

THE

MANUAL

GAS

SHUTOFF

VALVE

EXTERNAL

TO

THE

UNIT

BEFORE

TURNING

OFF

THE

ELECTRICAL

SUPPLY

.

WARNING

T

O

AVOID

PROPERTY

DAMAGE

,

PERSONAL

INJURY

OR

DEATH

,

DO

NOT

FIRE

GAS

UNIT

WITH

FLUE

BOX

COVER

REMOVED

.

WARNING