21

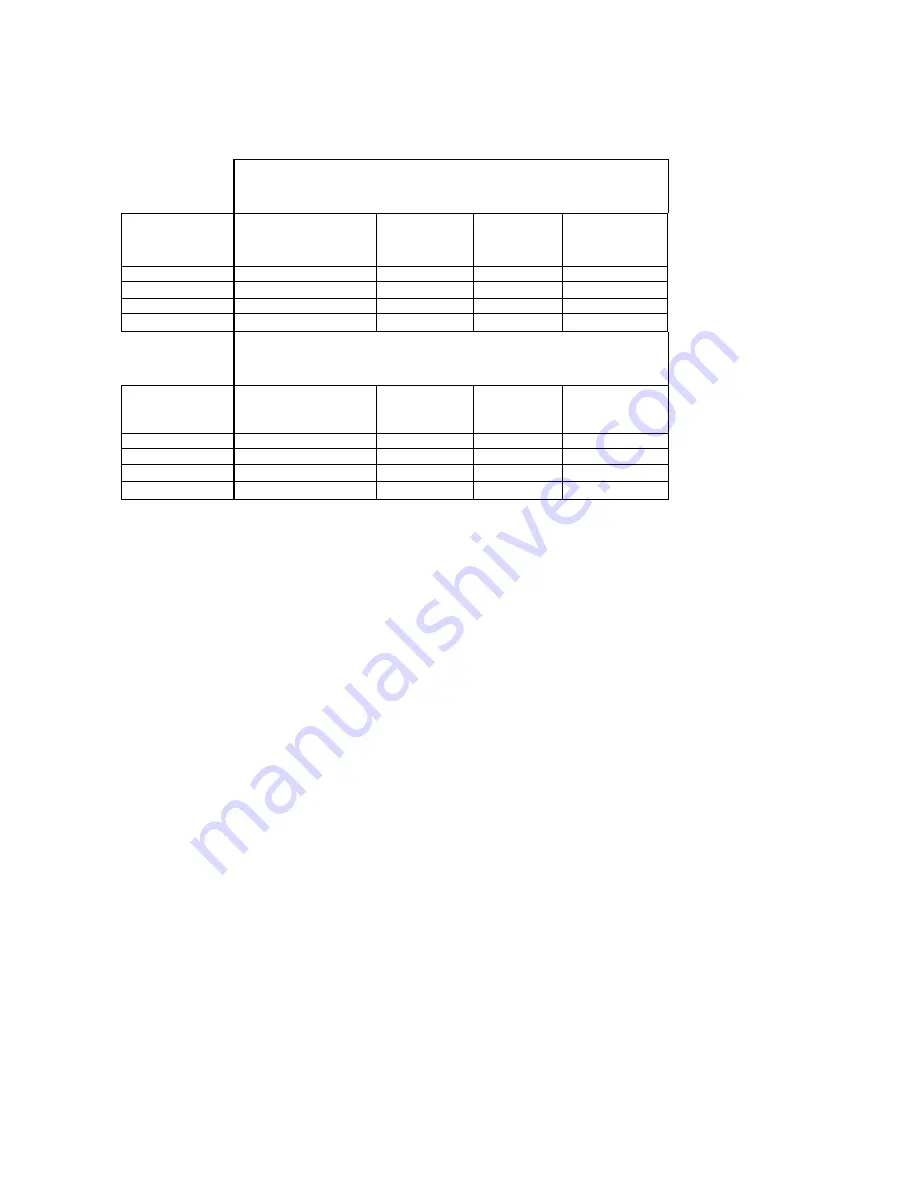

TYPICAL FLOW RATES FOR INSECTICIDES

TABLE 1

FLOW RATE

VEHICLE

SPEED

MPH

DURSBAN

(CHLORPYRIFOS)

OZ/MIN

PYRETHRIN

OZ/MIN

D1BROM

OZ/MIN

TECHNICAL

M

A

LATHION

OZ/MIN

5

1.4-2.7

2.0-2.5

3.0-6.0

1.0-2.1

10

2.7-5.3

4.0 - 5.0

6.0-12.0

2.0-4.3

15

—

6.0-7.5

9.0-18.0

3.0-6.5

20

—

8.0-10.0

—

4.0-8.6

FLOW RATE

VEHICLE SPEED

KM/HR

DURSBAN

(CHLORPYRIFOS)

ML/MIN

PYRETHRIN

ML/MIN

DIBROM

ML/MIN

TECHNICAL

MALATHION

ML/MIN

8

42-81

60-75

90-180

30-63

16

81 -159

120-150

180-360

60-129

24

—

180-225

270 - 540

90-195

32

—

240 - 300

—

120-258

CAUTION

The above rates are examples of typical application rates found on their

respective formulation labels. Refer to the label of your formulation to determine

the actual application rate before calibrating your machine to any of the above

flow rates.

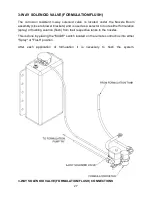

Once the flow ability of the formulation to be sprayed has been determined, and the

formulation pump has been calibrated, select one of the three tables (see next page)

that is closest to the flow ability of the formulation to be sprayed (34, 40 or 88 seconds).

Then match the closest flow rate in the left hand column with the flow rate specified on

the formulation label. A boom pressure can then be selected that will produce a particle

size in accordance with the formulation label. Remember, with a constant flow rate

supplied to the nozzle system, increasing nozzle boom pressure will decrease particle

size.

Summary of Contents for MAXI-PRO 2D ULV

Page 6: ...6 MAJOR COMPONENTS DIAGRAM ...

Page 9: ...9 ...

Page 39: ...39 ...

Page 43: ...43 BOOM ASSEMBLY MAXI PRO 2D P N 64905 ...

Page 50: ...50 ...