Installation and service manual: Postmix tower

Ribbon

68

Cornelius Deutschland GmbH

Document no. TD0000100

Version: 06/11/2017, Index 0

8.2.10

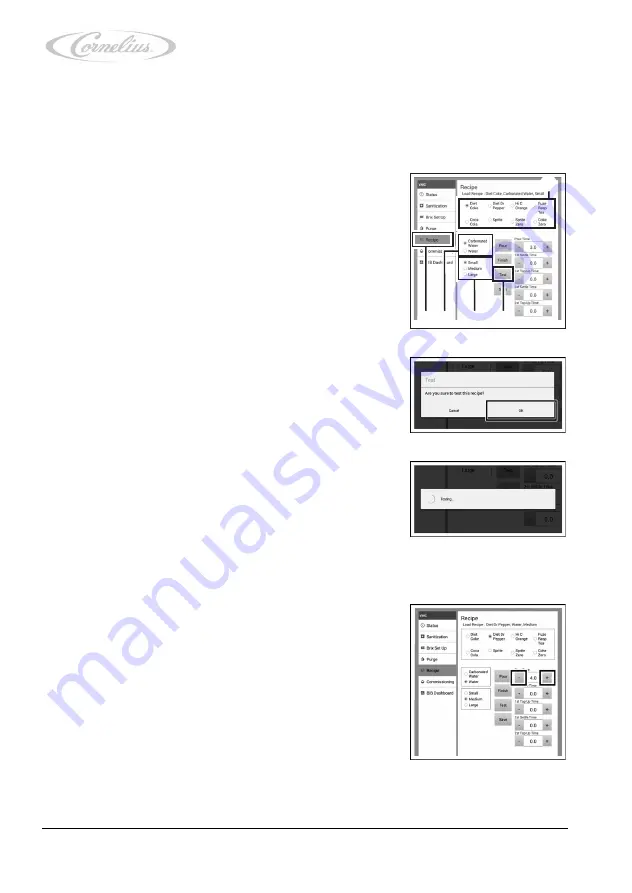

Checking and configuring settings in the “Recipe” menu

In the "Recipe" menu, the mixing ratio to the dispensing time can be checked and adjusted.

1.

Call up the “VMC Settings” menu (virtual machine control settings); see the document

“Tower operator manual”, document no. TD0000000

.

2.

Check the mixing ratio to the dispensing time as follows:

a.

Press “Recipe” (Figure 92/5).

b.

Select a product by pressing the required one.

(Figure 92/1).

c.

Press the basic ingredient to select it according

to the chosen product (Figure 92/4).

d.

Select the cup size (Figure 92/3) you wish to

check.

e.

Place a cup under the dispensing nozzle.

f.

Press “Test” (Figure 92/2).

A new window opens.

g.

Confirm the window message by pressing “OK”.

The selected beverage is dispensed.

h.

Check the mixing ratio for all products and cup

sizes.

•

If the settings are correct, return to the ser-

vice menu and continue with the next step,

.

•

If the settings are not correct, you can set

the mixing ratio to the dispensing time as follows:

1.

Increase or reduce the dispensing time using “+” or “-”.

2

1

3

4

5

Figure 92

Figure 93

Figure 94

Figure 95