Operator’s Manual: Commercial Seed Tender (CST-34 Series)

4-8

01.2016

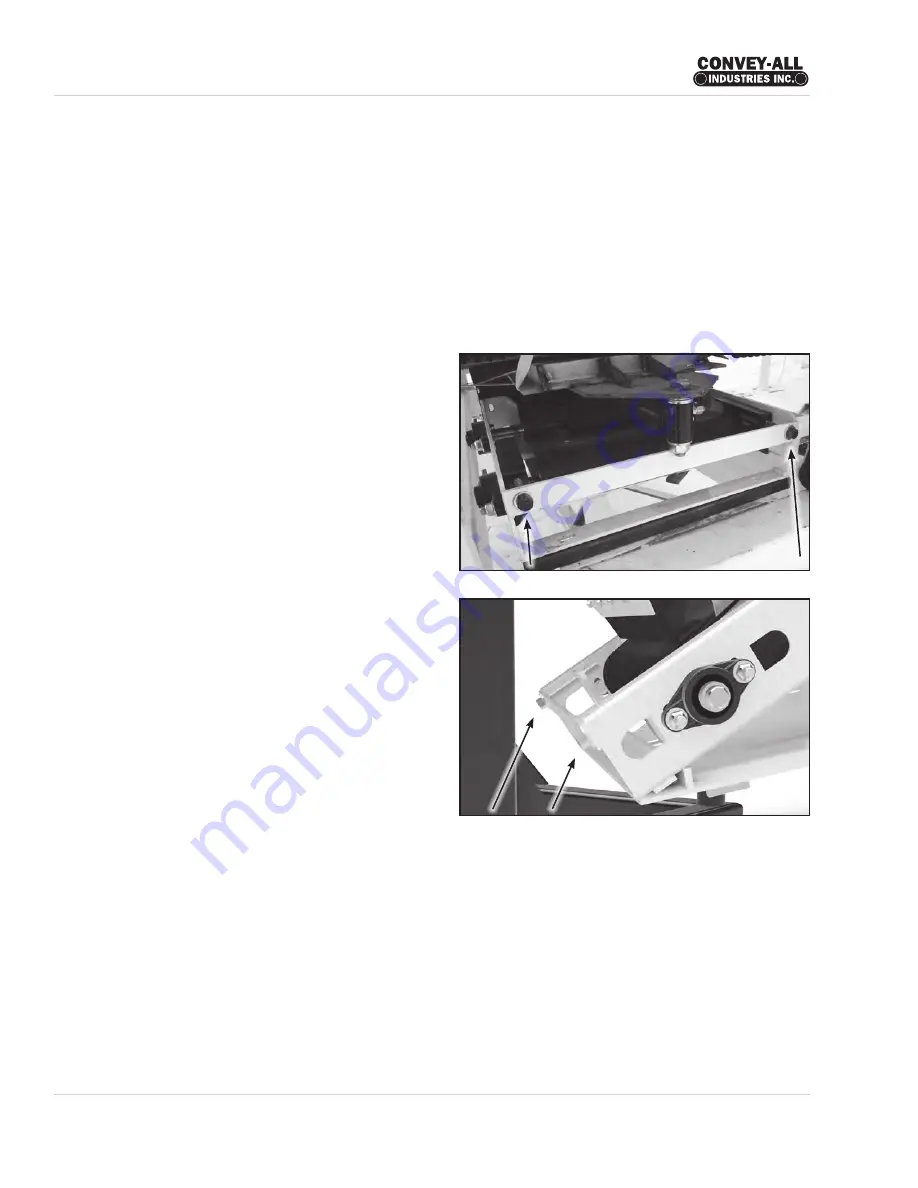

Fig 41 - Tension Bolts, Slave Conveyor

4.3.2 Conveyor Belt Tension:

The tension and alignment of the conveyor belts

should be checked daily to insure proper function.

Replace the belt when damaged or badly worn. To

maintain belt, follow this procedure:

1. Place all controls in their neutral or off position.

2. Stop engine, remove ignition key and lock-out.

Note:

The belt is tensioned correctly

when it does not slip

on the drive roller when loaded.

3. The tension is set and controlled by the tension

bolts on the tail end of both conveyors.

4. Loosen the tail roller bearing assembly.

5. On the slave conveyor, move both tension bolts

the same amount to tension the belt.

6. On the Folding Conveyor, tighten or loosen

tension bolts until the spring measures 3-3/4

inches (95 mm).

7. Tighten the roller assemblies.

8. Run the conveyor to test its tension.

4.3.3 Conveyor Belt Alignment:

The belt is properly aligned when the it runs in the

centre of the frame and the rollers. Be sure to run the

conveyor a full revolution to check the entire belt.

The belt can move from side-to-side while it is turning

as long as it doesn't contact the sides. If it touches the

sides, it must be aligned.

Note:

If belt is out of alignment,

it will move to the loose side.

Tighten loose side or loosen tight side.

1. Loosen the roller bearing assembly on the correct

side. of either the drive or tail roller.

2. Move the bearing assembly to align the belt.

3. Tighten the bearing assembly, then run the belt to

check alignment. Repeat, until it runs centred.

Fig 42 - Tension Bolts, Folding Conveyor

Summary of Contents for CST-1634

Page 1: ...COMMERCIAL SEED TENDER Models CST 1634 CST 1834 CST 2034 CST 2434 OPERATOR S MANUAL ...

Page 4: ......

Page 49: ......