8

PC1000i Crimper – Operator Manual

PC1000i Crimper with CrimpIQ™ Controller

PC1000i Features

Quickly Interchangeable Adapter Dies.

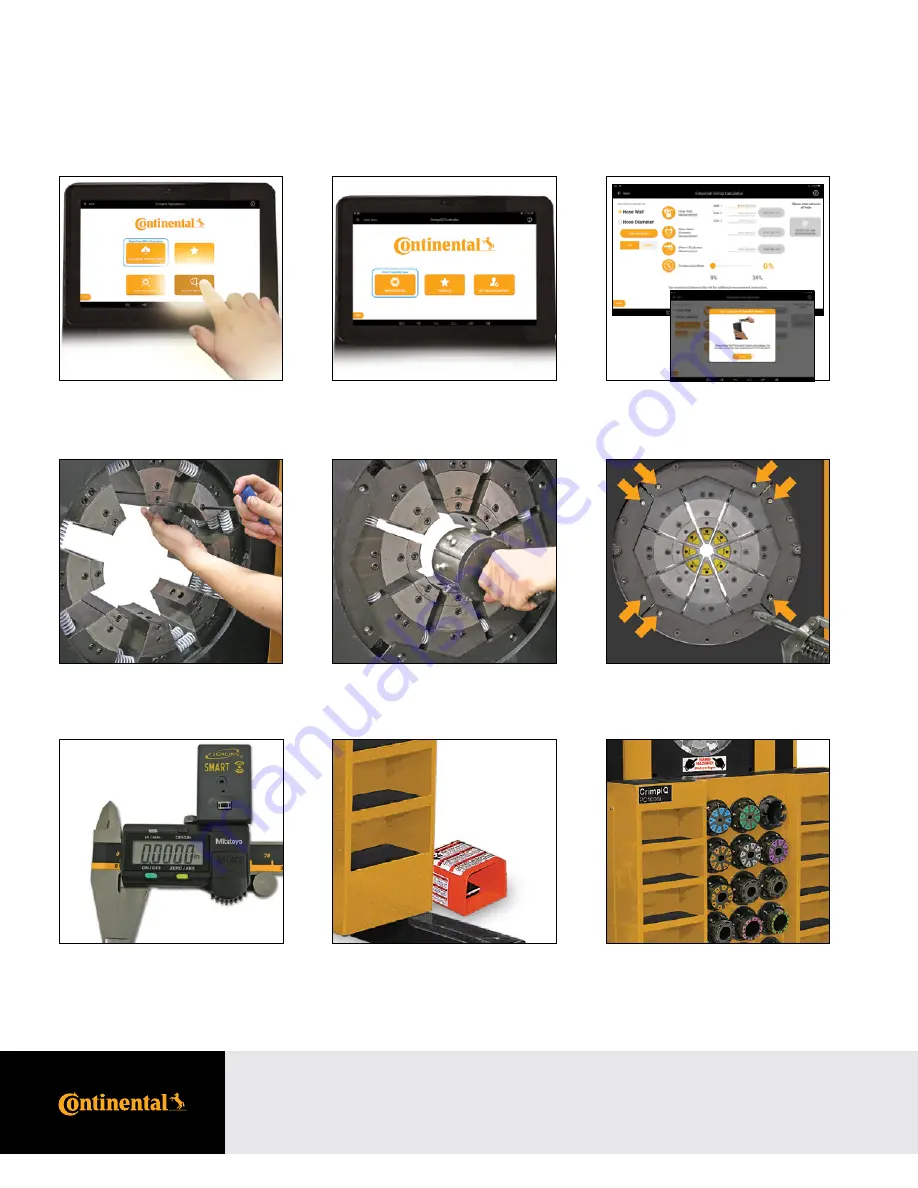

Continental CrimpIQ™ controller, the

future of crimping at your fingertips.

10-inch color capacitive touchscreen

and user- friendly navigation.

Intuitive screens lead the operator

through the setup and crimping process.

Quick change tool makes die changes

a quick and simple process.

Easy grease maintenance through the

lubrication fittings.

Built-in die shelves and storage pockets

keeps frequently used die sets readily

available.

Foot pedal for use in semi and full

automatic mode.

PC1000i Features

Continental CrimpIQ™ controller

supports bluetooth calipers to input

crimp diameter measurements.

Saving time and entering accurate

measurements.