Installation Instructions

Positioning module

Conductor rail program 0832, C-rail,

Console, ProShell

MV0800-0015a-EN

www.conductix.com

translated document

Page 20 of 23

6.2

Interruption of the positioning band at transition points, expansion points, etc.

If the positioning band has to be interrupted, it is recommended to cut out a complete code label, e.g. to cut the positioning band at

an expansion point or for a screw head.

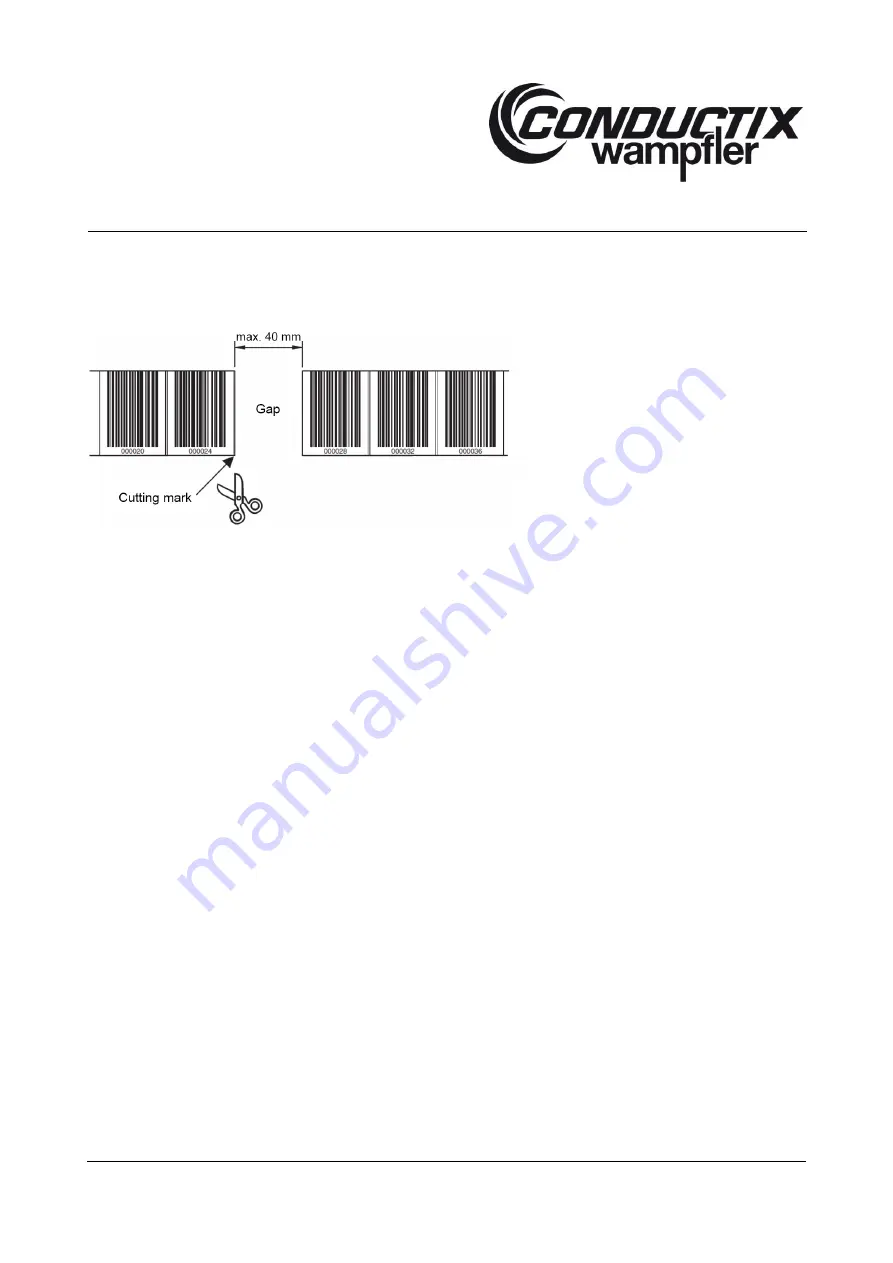

Fig. 33: Interrupting the positioning band

The separation must take place at the cut mark printed on the positioning band and must not be larger than 40 mm.

Notes for cutting:

Expansion joints up to a width of several millimeters can simply be glued over. The positioning band may not be inter-

rupted at this point.

Glue over protruding screw heads. Cut out the code label covering the screw head at the cutting edges.

If application results in a gap, it is recommended that the positioning band be affixed over this gap and then cut at the

relevant cutting marks. If the gap is so small that the scanning beam can detect the code label either to the left or to the right

of the gap, measured values will be supplied without interruption. If the scanning beam cannot scan a code label completely,

the BPS 34 returns a value of "0". As soon as the BPS 34 can scan a complete code label again, it calculates the next

position value.

The maximum gap between two positioning band positions that will not affect the measured value is 40 mm.