13

www.combisteel.com

8. Maintenance

IMPORTANT: Repair and maintenance work must be carried out by the Official Technical Service from

Combisteel BV or those authorized by them.

IMPORTANT: Before carrying out any maintenance, cleaning, or repair operations on the electrical part of the

appliance, the electrical supply must be disconnected at the mains switch and the appliance must be unplugged

from the electrical supply. As far as possible, work must be carried out with the machine disconnected and with

no voltage. For all operations that could be dangerous the operator must have the possibility of checking that

the plug remains always removed from the electrical supply. If the machine halts to carry out maintenance, there

is a residual risk when opening spiral protection grille that this will continue to rotate through inertia. This risk

does not exist if the machine is working fully loaded, since in this case the inertia of the spiral when opening the

grille will be cancelled out by the product being prepared (kneading). Moreover, if the machine is carrying out

an empty work cycle, there is the possibility that the spiral, due to inertia, takes a few seconds to come to a

complete halt. In this case the operator should take great care when accessing the hazardous area.

8.1 When the machine is new

The machine should be tested with a little product so that possible manufacturing residues can be removed

before starting the production phase.

8.2 Daily Operations

Clean using hot water and food-safe degreaser, and dry with a clean cloth., after each day’s work parts that come

into direct contact with the dough.: contacts column, spiral and bowl.

8.3 15 hours of work

Check the tautness of the spiral movement transmission belts and the tautness of the bowl movement

transmission belts.

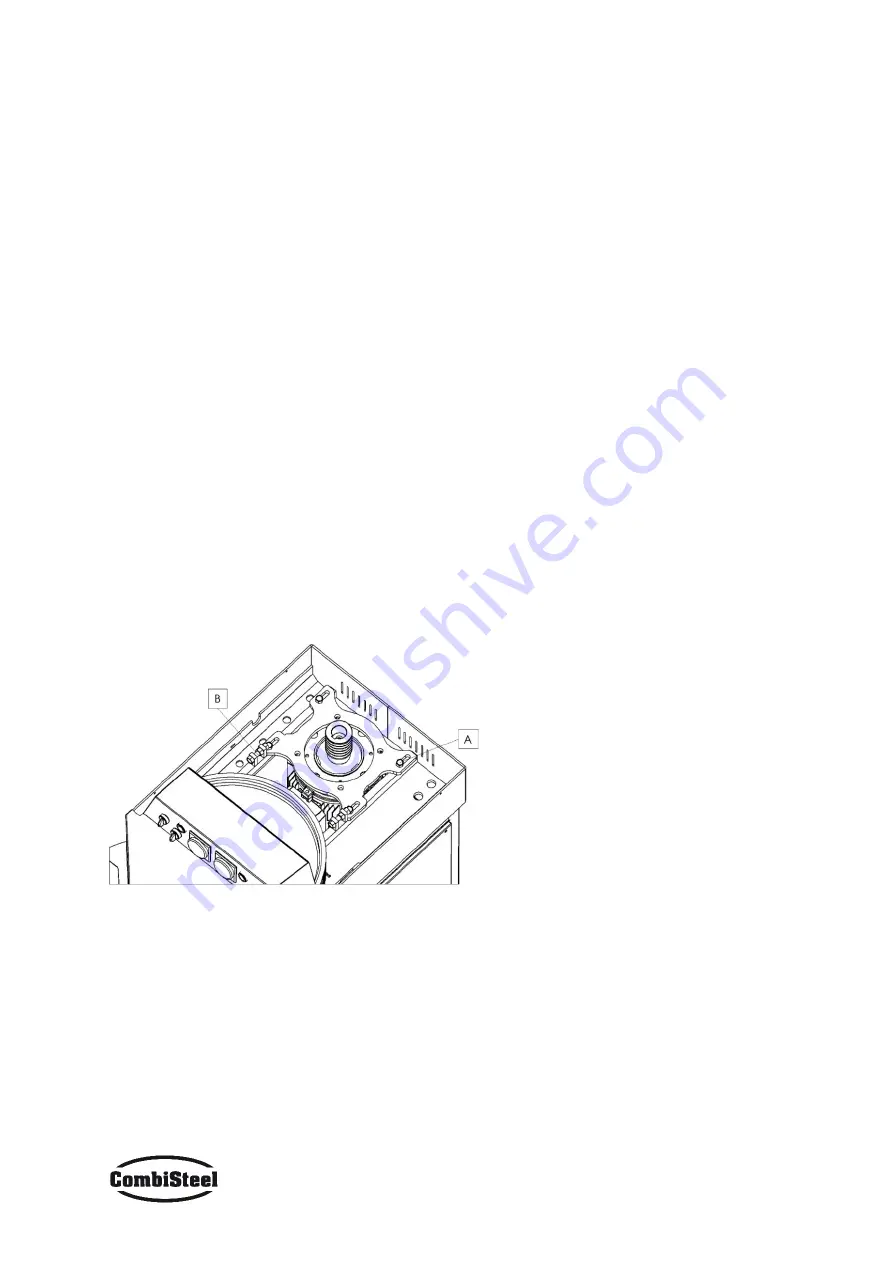

8.3.1 Spiral Movements belts tautness

The belts must be regulated if, during the work

cycle, the deceleration of the spiral is observed.

1. Release the screws (A)

2. Tighten the belts effectively use the screws (B).

3. Tighten the screws (A).

8.3.2 Others Models

The belts must be regulated if, during the work cycle, the deceleration of the spiral is observed.

1. Remove the head casing.

2. Release the four motor support screws (pos. A), without fully unscrewing, and then loosen the nut (pos. B).

3. Tighten the belts properly using the screw (pos. C) and lock the nut (pos. B).

4. Tighten the four motor support screws (pos. A).

5. Replace the head casing.