34

After Sales Support

1300 663 907

Model Number

HE150272

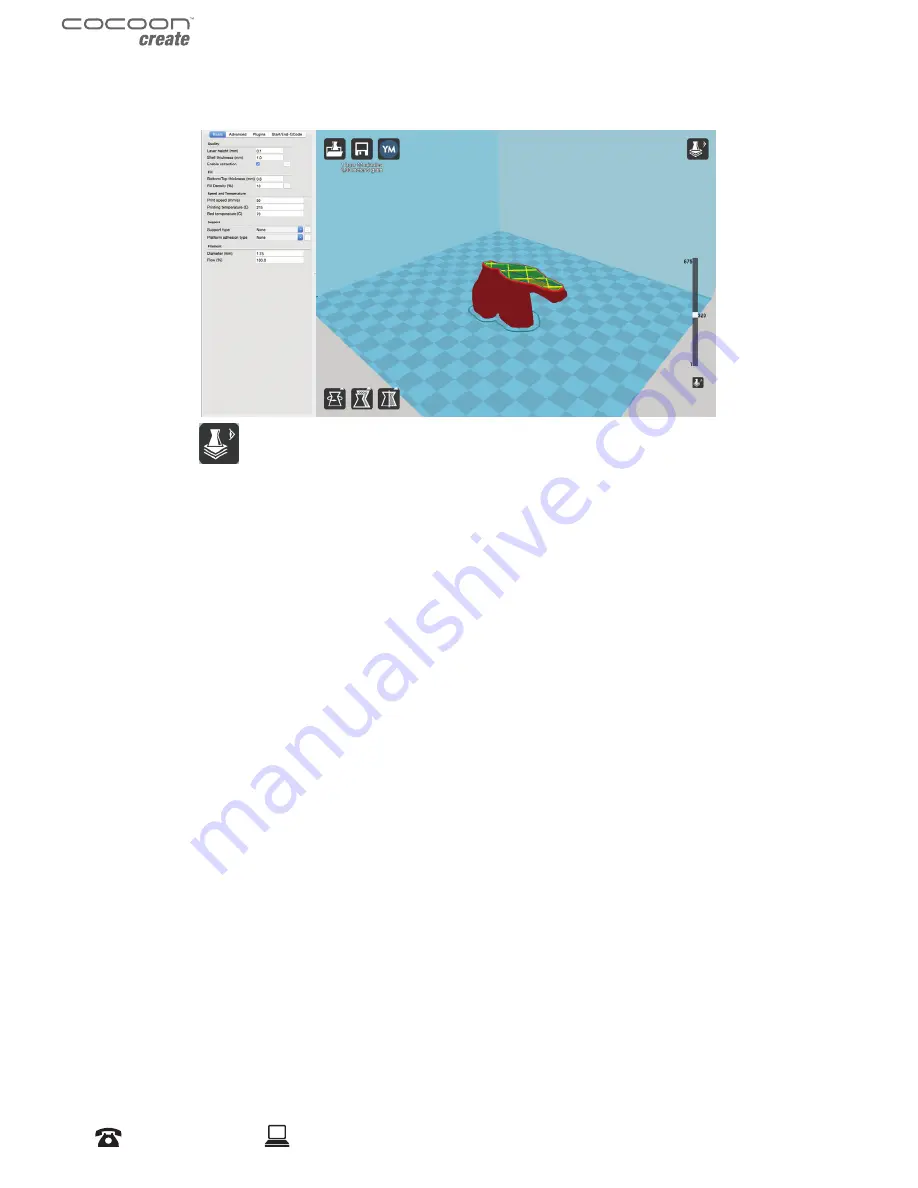

View Mode

This mode allows you to view your model in a variety of different ways.

This can be helpful for spotting issues before the print even starts.

Normal

This is the standard view and shows the solid outer surfaces of the model.

Overhang

Overhang mode shows where your model may need support material. Red highlighted areas show

overhangs and more severe angles and areas where support material is recommended. Refer to

page 38 for information on how to add support material to your model.

Ghost

Ghost view mode makes the model translucent to allow you to see what is behind it.

Xray

Xray is very similar to Ghost mode. It will allow you to see into objects, ensuring that inner details

are correct.

Layers

To view the toolpath of your print head and to ensure no skipped layers or gaps, use this option.

Use the slide bar on the right hand side of the window to move up and down through the

toolpath layers.

Using Cura

.

Summary of Contents for HE150272

Page 1: ... INSTRUCTION MANUAL Model Number HE150272 ...

Page 2: ... ...

Page 57: ... ...

Page 59: ... ...

Page 60: ... ...